Product Description

Low Backlash Worm Gearbox Efficiency Servo Gear Boxes reducer zero electric transmission motor China Manufacturers for Energy Aerospace Industrial Gearboxes

The low backlash drive units HPCNHS type are available in 4 sizes. Each size includes 2 ratios which are 30:1 and 60:1.

The drive units HPCNHS are built with a minimum backlash which can be adjusted due to the duplex toothing of the gears.

The low backlash drive units are built for medium power transmission.

Worm Gear Units:

The NHS-Range gearboxes is available in 4 model sizes and 2 standard ratios.The gearbox size is identical to the centreline distance.

Low backlash Features :

— Worm gear gyration backlash can be adjusted to less than 1 arc.

— Reducer can be re-adjusted the gap after using .

— Input with coupling : reliable without backlash .

— Output using conical clamping ring couplings : reliable without backlash.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

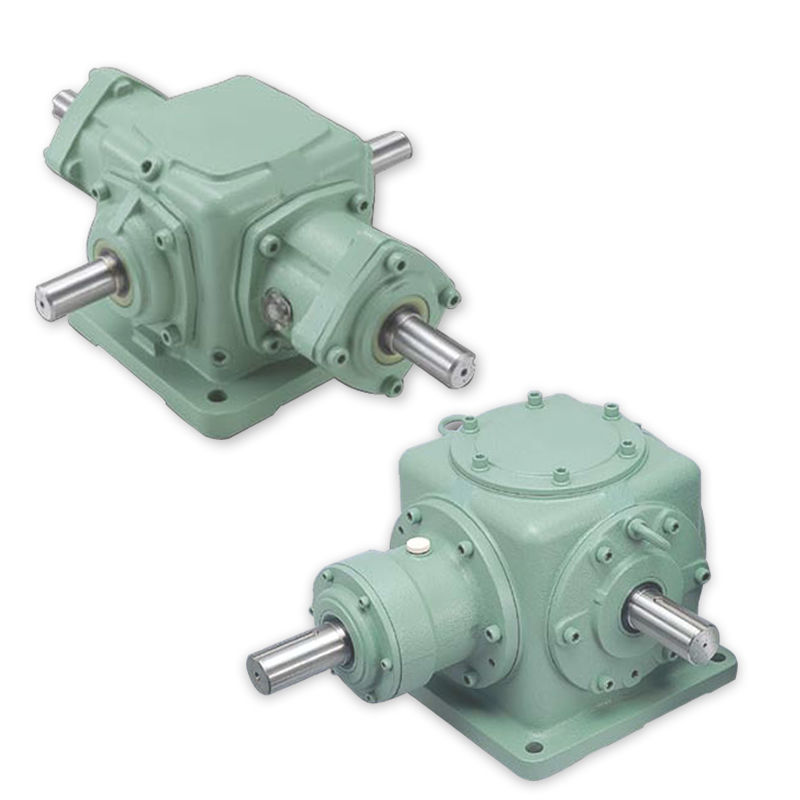

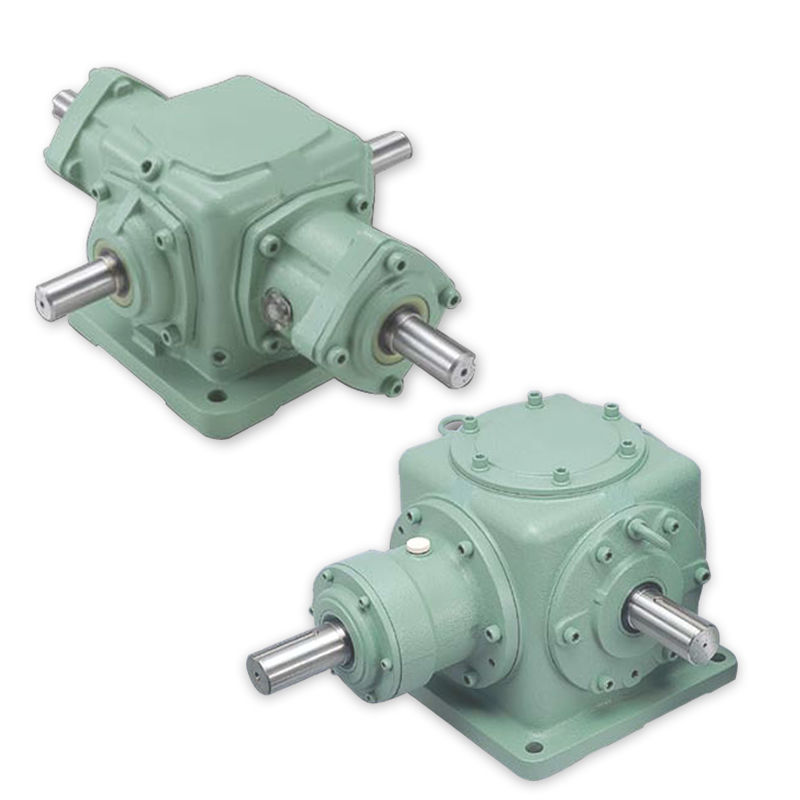

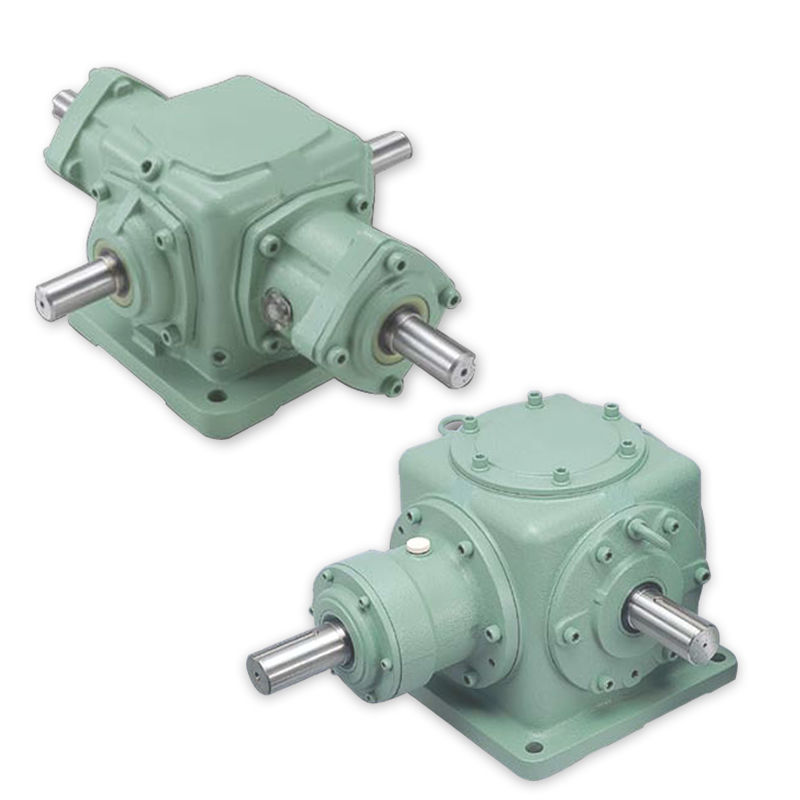

Minimizing Backlash and Ensuring Efficient Power Transfer in Miter Gearboxes

Miter gearboxes are meticulously designed to minimize backlash and ensure efficient power transfer, contributing to smooth and reliable operation in various mechanical systems.

Backlash, the slight movement or play between mating gears, can lead to imprecise motion and reduced accuracy. To address this, miter gearboxes incorporate features such as precision-machined gear teeth, high-quality bearings, and precise alignment of gears and shafts. These design elements help minimize the clearance between gear teeth, reducing or eliminating backlash and ensuring consistent motion transfer.

Efficient power transfer in miter gearboxes is achieved through careful consideration of gear geometry, tooth profiles, and material selection. Engineers optimize gear tooth shapes to minimize friction and maximize contact area between mating gears. Additionally, high-quality materials with appropriate hardness and surface finish are chosen to enhance durability and reduce energy losses due to friction.

The lubrication system also plays a critical role in efficient power transfer. Proper lubrication reduces friction, dissipates heat, and prevents wear, contributing to the overall efficiency of the gearbox.

Overall, the design of miter gearboxes focuses on tight tolerances, precision manufacturing, and thoughtful engineering to minimize backlash and maximize power transfer efficiency, resulting in reliable and high-performance mechanical systems.

Key Benefits of Using Miter Gearboxes in Angular Transmission Applications

Miter gearboxes offer several key benefits when used in applications requiring angular transmission:

- Precise Angle Transmission: Miter gearboxes excel at transmitting rotational motion at specific angles, ensuring accurate and controlled angular adjustments.

- Compact Design: Their compact and space-saving design allows for efficient integration into machinery and equipment with limited space.

- High Efficiency: Miter gearboxes are engineered for efficient power transmission, minimizing energy losses during angular motion transfer.

- Smooth Operation: The meshing of bevel gears in miter gearboxes results in smooth and stable motion, reducing vibration and noise.

- Wide Range of Angles: Miter gearboxes can handle a broad range of angle requirements, making them versatile for various applications.

- Enhanced Precision: These gearboxes enable precise positioning and alignment of components, crucial in industries like automotive manufacturing.

- Robust and Durable: Constructed from high-quality materials, miter gearboxes offer durability and can withstand demanding operational conditions.

- Customizability: Miter gearboxes can be designed and customized to meet specific angle transmission needs in different industries.

Overall, miter gearboxes are a valuable solution for applications that require accurate and reliable angular transmission, contributing to improved performance and quality in various industries.

Function of Miter Gearbox in Mechanical Systems

A miter gearbox is a type of gear arrangement that allows rotational motion to be transmitted at a 90-degree angle between intersecting shafts. It consists of two bevel gears with perpendicular axes, which makes it suitable for changing the direction of motion in a mechanical system.

Miter gearboxes function by meshing the teeth of the two bevel gears, which are cut at an angle of 45 degrees. As one gear rotates, its teeth engage with the teeth of the other gear, transmitting torque and motion perpendicular to the input shaft. This 90-degree redirection of motion is crucial for applications where space constraints or specific mechanical configurations require changes in direction.

These gearboxes are commonly used in situations where components need to be rotated or aligned at right angles, such as in automotive steering systems, printing presses, woodworking machinery, and more. The ability to efficiently transfer motion at a 90-degree angle makes miter gearboxes essential in various industrial and mechanical applications.

editor by CX 2024-05-15

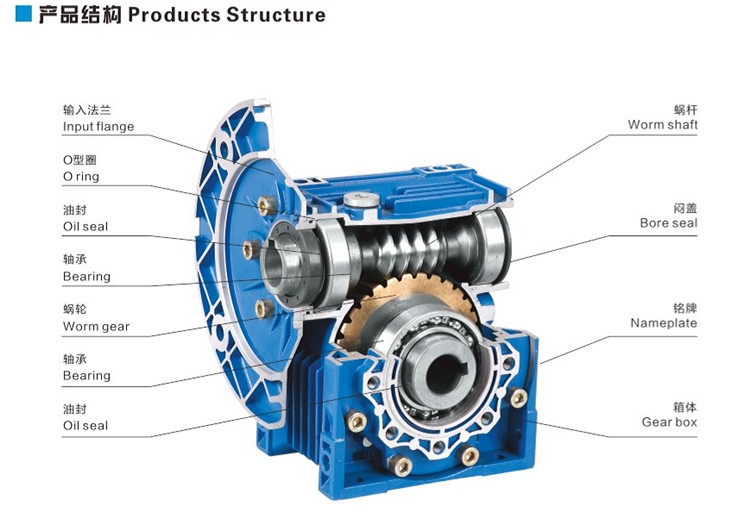

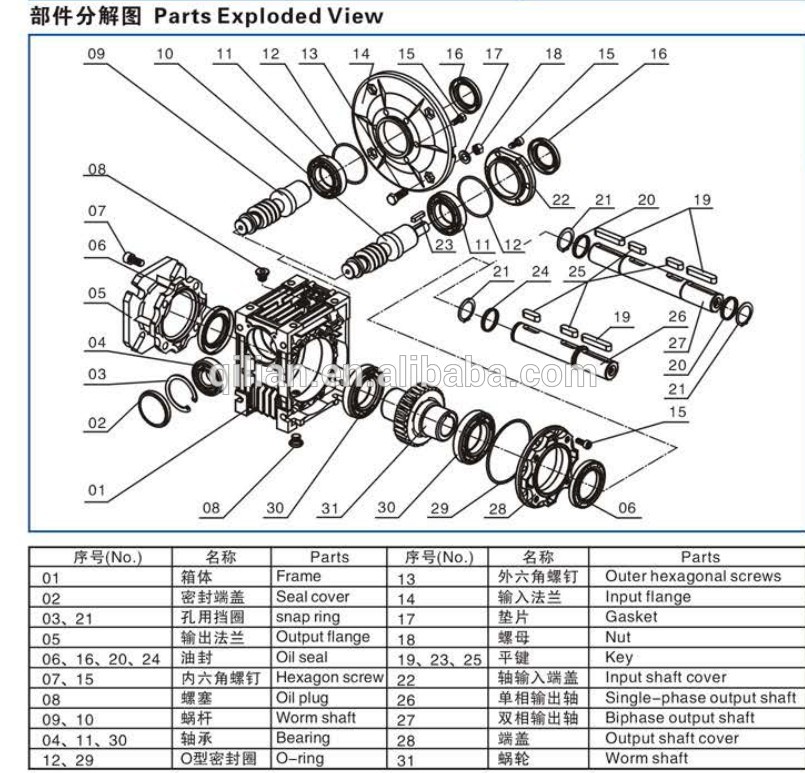

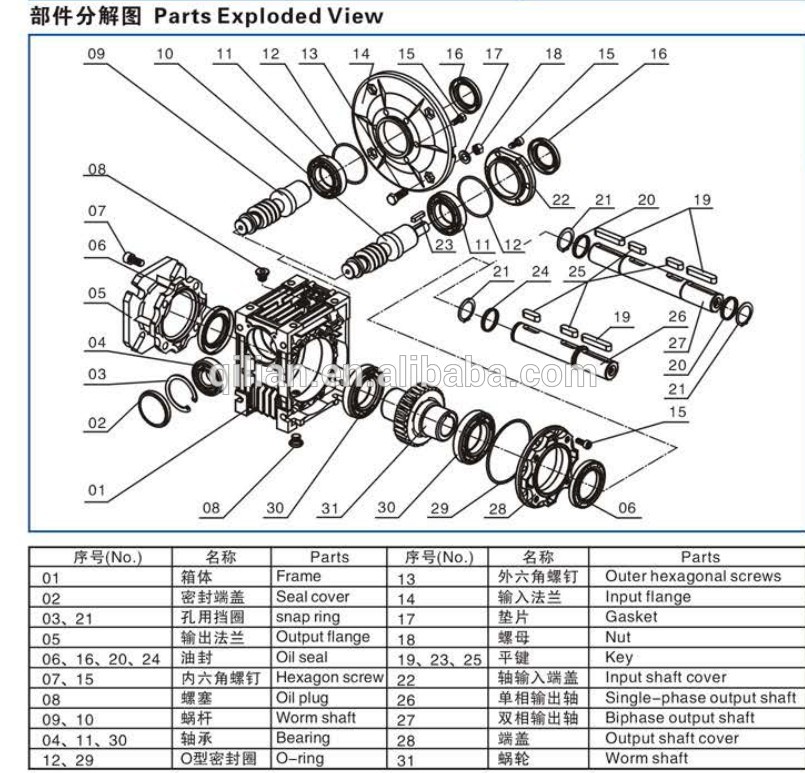

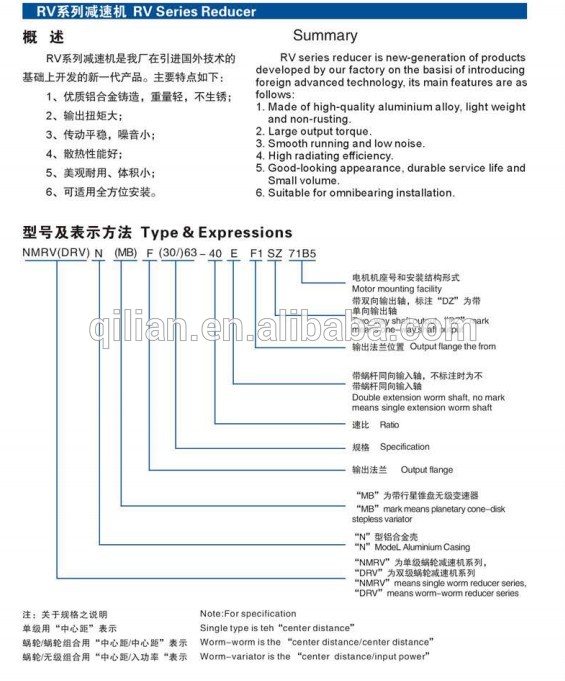

China Hangzhou NMRV NMRW NRV NRW series two double stage worm gear reducer electric motor worm reducer gearbox gear motor couplings bevel gearbox

Guarantee: 1 12 months

Relevant Industries: Hotels, Garment Stores, Developing Material Shops, Manufacturing Plant, Machinery Restore Retailers, Foodstuff & Beverage Factory, Farms, Cafe, House Use, Retail, Meals Shop, Printing Retailers, Construction works , Vitality & Mining, Foodstuff & Beverage Retailers, Advertising Organization, Other

Bodyweight (KG): 15 KG

Custom-made assistance: OEM, ODM, OBM

Gearing Arrangement: Worm

Output Torque: 1.8-2430N.M

Input Pace: 750-1500rpm

Output Velocity: fourteen-280rpm

clolor: Blue/gray/silver

Packaging Details: Cartons and powerful wooden circumstance for sea transporation

Port: HangZhou,ZheJiang

| MODEL NO. | NMRV a hundred thirty 150 | Installation | Torque Arm Sort | Step | Stepless |

| Type | Worm Gear box | Output Pace | 14.4-192rpm | Warranty | 1 a long time |

| Transport bundle | Standard Sea Deserving Package deal | Input Speed | 1440rpm | Lubricant | Synthetic & Mineral |

| Color | RAL5571, Blue, Silver | Seal | NAK seal from ZheJiang | Worm | 20cr |

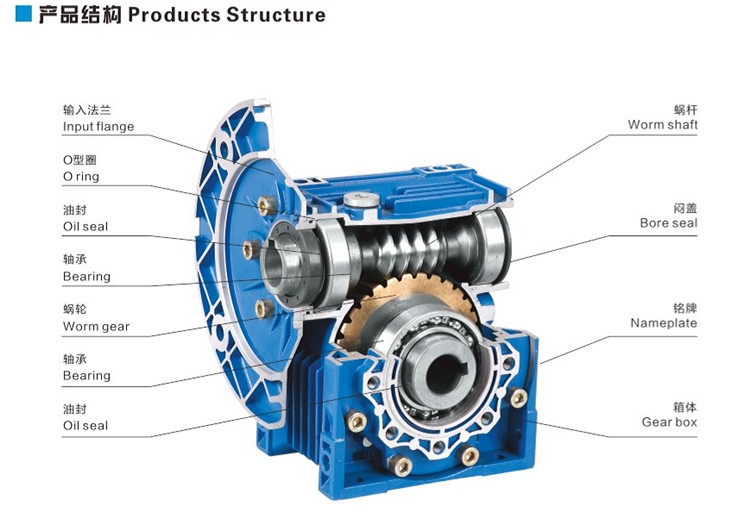

What Is a Gearbox?

There are several factors to consider when choosing a gearbox. Backlash, for example, is a consideration, as it is the angle at which the output shaft can rotate without the input shaft moving. While this isn’t necessary in applications without load reversals, it is important for precision applications involving load reversals. Examples of these applications include automation and robotics. If backlash is a concern, you may want to look at other factors, such as the number of teeth in each gear.

Function of a gearbox

A gearbox is a mechanical unit that consists of a chain or set of gears. The gears are mounted on a shaft and are supported by rolling element bearings. These devices alter the speed or torque of the machine they are used in. Gearboxes can be used for a wide variety of applications. Here are some examples of how gearboxes function. Read on to discover more about the gears that make up a gearbox.

Regardless of the type of transmission, most gearboxes are equipped with a secondary gear and a primary one. While the gear ratios are the same for both the primary and secondary transmission, the gearboxes may differ in size and efficiency. High-performance racing cars typically employ a gearbox with two green and one blue gear. Gearboxes are often mounted in the front or rear of the engine.

The primary function of a gearbox is to transfer torque from one shaft to another. The ratio of the driving gear’s teeth to the receiving member determines how much torque is transmitted. A large gear ratio will cause the main shaft to revolve at a slower speed and have a high torque compared to its counter shaft. Conversely, a low gear ratio will allow the vehicle to turn at a lower speed and produce a lower torque.

A conventional gearbox has input and output gears. The countershaft is connected to a universal shaft. The input and output gears are arranged to match the speed and torque of each other. The gear ratio determines how fast a car can go and how much torque it can generate. Most conventional transmissions use four gear ratios, with one reverse gear. Some have two shafts and three inputs. However, if the gear ratios are high, the engine will experience a loss of torque.

In the study of gearbox performance, a large amount of data has been collected. A highly ambitious segmentation process has yielded nearly 20,000 feature vectors. These results are the most detailed and comprehensive of all the available data. This research has a dual curse – the first is the large volume of data collected for the purpose of characterization, while the second is the high dimensionality. The latter is a complication that arises when the experimental gearbox is not designed to perform well.

Bzvacklash

The main function of a gearhead is to multiply a moment of force and create a mechanical advantage. However, backlash can cause a variety of issues for the system, including impaired positioning accuracy and lowered overall performance. A zero backlash gearbox can eliminate motion losses caused by backlash and improve overall system performance. Here are some common problems associated with backlash in gearheads and how to fix them. After you understand how to fix gearbox backlash, you’ll be able to design a machine that meets your requirements.

To reduce gearbox backlash, many designers try to decrease the center distance of the gears. This eliminates space for lubrication and promotes excessive tooth mesh, which leads to premature mesh failure. To minimize gearbox backlash, a gear manufacturer may separate the two parts of the gear and adjust the mesh center distance between them. To do this, rotate one gear with respect to the fixed gear, while adjusting the other gear’s effective tooth thickness.

Several manufacturing processes may introduce errors, and reducing tooth thickness will minimize this error. Gears with bevel teeth are a prime example of this. This type of gear features a small number of teeth in comparison to its mating gear. In addition to reducing tooth thickness, bevel gears also reduce backlash. While bevel gears have fewer teeth than their mating gear, all of their backlash allowance is applied to the larger gear.

A gear’s backlash can affect the efficiency of a gearbox. In an ideal gear, the backlash is zero. But if there is too much, backlash can cause damage to the gears and cause it to malfunction. Therefore, the goal of gearbox backlash is to minimize this problem. However, this may require the use of a micrometer. To determine how much gearbox backlash you need, you can use a dial gauge or feeler gauge.

If you’ve been looking for a way to reduce backlash, a gearbox’s backlash may be the answer. However, backlash is not a revolt against the manufacturer. It is an error in motion that occurs naturally in gear systems that change direction. If it is left unaccounted for, it can lead to major gear degradation and even compromise the entire system. In this article, we’ll explain how backlash affects gears and how it affects the performance of a gearbox.

Design

The design of gearboxes consists of a variety of factors, including the type of material used, power requirements, speed and reduction ratio, and the application for which the unit is intended. The process of designing a gearbox usually begins with a description of the machine or gearbox and its intended use. Other key parameters to consider during gearbox design include the size and weight of the gear, its overall gear ratio and number of reductions, as well as the lubrication methods used.

During the design process, the customer and supplier will participate in various design reviews. These include concept or initial design review, manufacturing design validation, critical design review, and final design review. The customer may also initiate the process by initiating a DFMEA. After receiving the initial design approval, the design will go through several iterations before the finalized design is frozen. In some cases, the customer will require a DFMEA of the gearbox.

The speed increaser gearboxes also require special design considerations. These gearboxes typically operate at high speeds, causing problems with gear dynamics. Furthermore, the high speeds of the unit increase frictional and drag forces. A proper design of this component should minimize the effect of these forces. To solve these problems, a gearbox should incorporate a brake system. In some cases, an external force may also increase frictional forces.

Various types of gear arrangements are used in gearboxes. The design of the teeth of the gears plays a significant role in defining the type of gear arrangement in the gearbox. Spur gear is an example of a gear arrangement, which has teeth that run parallel to the axis of rotation. These gears offer high gear ratios and are often used in multiple stages. So, it is possible to create a gearbox that meets the needs of your application.

The design of gearboxes is the most complex process in the engineering process. These complex devices are made of multiple types of gears and are mounted on shafts. They are supported by rolling element bearings and are used for a variety of applications. In general, a gearbox is used to reduce speed and torque and change direction. Gearboxes are commonly used in motor vehicles, but can also be found in pedal bicycles and fixed machines.

Manufacturers

There are several major segments in the gearbox market, including industrial, mining, and automotive. Gearbox manufacturers are required to understand the application and user industries to design a gearbox that meets their specific requirements. Basic knowledge of metallurgy is necessary. Multinational companies also provide gearbox solutions for the power generation industry, shipping industry, and automotive industries. To make their products more competitive, they need to focus on product innovation, geographical expansion, and customer retention.

The CZPT Group started as a small company in 1976. Since then, it has become a global reference in mechanical transmissions. Its production range includes gears, reduction gearboxes, and geared motors. The company was the first in Italy to achieve ISO certification, and it continues to grow into one of the world’s leading manufacturers of production gearboxes. As the industry evolves, CZPT focuses on research and development to create better products.

The agriculture industry uses gearboxes to implement a variety of processes. They are used in tractors, pumps, and agricultural machinery. The automotive industry uses gears in automobiles, but they are also found in mining and tea processing machinery. Industrial gearboxes also play an important role in feed and speed drives. The gearbox industry has a diverse portfolio of manufacturers and suppliers. Here are some examples of gearboxes:

Gearboxes are complex pieces of equipment. They must be used properly to optimize efficiency and extend their lifespan. Manufacturers employ advanced technology and strict quality control processes to ensure their products meet the highest standards. In addition to manufacturing precision and reliability, gearbox manufacturers ensure that their products are safe for use in the production of industrial machinery. They are also used in office machines and medical equipment. However, the automotive gearbox market is becoming increasingly competitive.

editor by czh

China high quality WJ(NMRV) small worm gear speed reducer worm gearbox with electric motor near me factory

Model Number: WJ30-WJ150

Gearing Arrangement: Worm

Output Torque: 2.6-1195N.m

Rated Power: 0.06-15KW

Input Speed: 1400rpm

Output Speed: 14-280rpm

Ratio: 7.5~100

Color: RAL9006 aluminium, RAL5571 blue or other

Input Form: IEC flange, solid shaft

Output Form: Solid shaft, Hollow shaft

Material: Cast iron / aluminium Worm Geared motor

Quality control system: ISO9001:2008

Packaging Details: small type Worm Geared motor—-paper carton and pallet, big type Worm Geared motor—-wood carton or wood pallet

Port: HangZhou or ZheJiang

Product photos:

WJ series reducer Technical Parameters:

Model

Shaft Dia.(mm)

Center Height

Output Flange Dia.

Power

Ratio

Permitted Torque

Weight

Solid(h6)

Hollow(h7)

(mm)

(mm)

(kw)

(Nm)

(KGS)

Wj30

14

14

40

80

0.09~0.3

7.5~100

22

1.5

Wj40

19

18/19

50

110

0.12~0.5

7.5~100

55

2.5

Wj50

25

25

60

125

0.18~0.7

7.5~100

120

4

Wj63

25

25

72

180

0.37~1.5

7.5~100

175

6

Wj75

28

28

86

200

0.55~3

7.5~100

280

9

Wj90

35

35

103

210

0.75~4

7.5~100

425

13.5

Wj110

42

42

127.5

270

1.1~5.5

7.5~100

585

43

Wj130

45

45

147.5

320

1.5~7.5

7.5~100

850

67

Wj150

50

50

170

320

2.2~15

7.5~100

1500

100

Remark: the weight is for basic model, without oil and motor

FAQ

Q1: I want to buy your products, how can I pay?

A: You can pay via T/T(30%+70%), L/C ,D/P, Brand new HangZhou Advance MB270A marine gearbox Medium-Low Duty Gearboxes for Ship Boat WEST UNION ,ESCROW etc. Especially ESCROW, which is guaranteed by Alibaba.com. It is safe and effective.

Q2: How can you guarantee the quality?

A: One year’s warranty against B/L date. If you meet with quality problem, please send us pictures or video to check, we promise to send spare parts or new products to replace. Our guarantee not include inappropriate operation or wrong specification selection.

Q3: How we select models and specifications?

A: You can email us the series code (for example: RC series helical gearbox) as well as requirement details, such as motor power, output speed or ratio, service factor or your application…as much data as possible. If you can supply some pictures or drawings, it is nice.

Q4: If we don’ high quality 23-88L .25H timing chain ,2045LW chain t find what we want on your website, what should we do?

A: We offer 3 options:1, You can email us the pictures, drawings or descriptions details. We will try to design your products on the basis of our standard models.

2, Our R&D department is professional for OEM/ODM products by drawing/samples, you can send us samples, we do customized design for your bulk purchasing.

3, We can develop new products if they have good market. We have already developed many items for special using successful, Dinsense straight planetary gearbox NEMA 23 for Delta CZPT servo motor applied in cnc wood machines such as special gearbox for agitator, cement conveyor, shoes machines and so on.

Q5: Can we buy 1 pc of each item for quality testing?

A: Yes, we are glad to accept trial order for quality testing

Q6: How about your product delivery time?

A: Normally for 20’container, it takes 25-30 workdays for worm and cycloid gearbox, 35-40 workdays for helical gearbox.

we also have other various iterms, welcome to contect us for more detail information and inquiry.

View More>>> High quality micro GM12-N20 12mm dc 1.5v-24volt gear motor with 3mm D-shaft >>

Worm Geared motor

Key Market Insights Related to Worm Reduction Gearboxes

A gearbox is a mechanical device that allows you to shift between different speeds or gears. It does so by using one or more clutches. Some gearboxes are single-clutch, while others use two clutches. You can even find a gearbox with closed bladders. These are also known as dual clutches and can shift gears more quickly than other types. Performance cars are designed with these types of gearboxes.

Backlash measurement

Gearbox backlash is a common component that can cause noise or other problems in a car. In fact, the beats and sets of gears in a gearbox are often excited by the oscillations of the engine torque. Noise from gearboxes can be significant, particularly in secondary shafts that engage output gears with a differential ring. To measure backlash and other dimensional variations, an operator can periodically take the output shaft’s motion and compare it to a known value.

A comparator measures the angular displacement between two gears and displays the results. In one method, a secondary shaft is disengaged from the gearbox and a control gauge is attached to its end. A threaded pin is used to secure the differential crown to the secondary shaft. The output pinion is engaged with the differential ring with the aid of a control gauge. The angular displacement of the secondary shaft is then measured by using the dimensions of the output pinion.

Backlash measurements are important to ensure the smooth rotation of meshed gears. There are various types of backlash, which are classified according to the type of gear used. The first type is called circumferential backlash, which is the length of the pitch circle around which the gear rotates to make contact. The second type, angular backlash, is defined as the maximum angle of movement between two meshed gears, which allows the other gear to move when the other gear is stationary.

The backlash measurement for gearbox is one of the most important tests in the manufacturing process. It is a criterion of tightness or looseness in a gear set, and too much backlash can jam a gear set, causing it to interface on the weaker part of its gear teeth. When backlash is too tight, it can lead to gears jamming under thermal expansion. On the other hand, too much backlash is bad for performance.

Worm reduction gearboxes

Worm reduction gearboxes are used in the production of many different kinds of machines, including steel and power plants. They are also used extensively in the sugar and paper industries. The company is constantly aiming to improve their products and services to remain competitive in the global marketplace. The following is a summary of key market insights related to this type of gearbox. This report will help you make informed business decisions. Read on to learn more about the advantages of this type of gearbox.

Compared to conventional gear sets, worm reduction gearboxes have few disadvantages. Worm gear reducers are commonly available and manufacturers have standardized their mounting dimensions. There are no unique requirements for shaft length, height, and diameter. This makes them a very versatile piece of equipment. You can choose to use one or combine several worm gear reducers to fit your specific application. And because they have standardized ratios, you will not have to worry about matching up multiple gears and determining which ones fit.

One of the primary disadvantages of worm reduction gearboxes is their reduced efficiency. Worm reduction gearboxes usually have a maximum reduction ratio of five to sixty. The higher-performance hypoid gears have an output speed of around ten to twelve revolutions. In these cases, the reduced ratios are lower than those with conventional gearing. Worm reduction gearboxes are generally more efficient than hypoid gear sets, but they still have a low efficiency.

The worm reduction gearboxes have many advantages over traditional gearboxes. They are simple to maintain and can work in a range of different applications. Because of their reduced speed, they are perfect for conveyor belt systems.

Worm reduction gearboxes with closed bladders

The worm and the gear mesh with each other in a combination of sliding and rolling movements. This sliding action is dominant at high reduction ratios, and the worm and gear are made of dissimilar metals, which results in friction and heat. This limits the efficiency of worm gears to around thirty to fifty percent. A softer material for the gear can be used to absorb shock loads during operation.

A normal gear changes its output independently once a sufficient load is applied. However, the backstop complicates the gear configuration. Worm gears require lubrication because of the sliding wear and friction introduced during movement. A common gear arrangement moves power at the peak load section of a tooth. The sliding happens at low speeds on either side of the apex and occurs at a low velocity.

Single-reduction gearboxes with closed bladders may not require a drain plug. The reservoir for a worm gear reducer is designed so that the gears are in constant contact with lubricant. However, the closed bladders will cause the worm gear to wear out more quickly, which can cause premature wear and increased energy consumption. In this case, the gears can be replaced.

Worm gears are commonly used for speed reduction applications. Unlike conventional gear sets, worm gears have higher reduction ratios. The number of gear teeth in the worm reduces the speed of a particular motor by a substantial amount. This makes worm gears an attractive option for hoisting applications. In addition to their increased efficiency, worm gears are compact and less prone to mechanical failure.

Shaft arrangement of a gearbox

The ray-diagram of a gearbox shows the arrangement of gears in the various shafts of the transmission. It also shows how the transmission produces different output speeds from a single speed. The ratios that represent the speed of the spindle are called the step ratio and the progression. A French engineer named Charles Renard introduced five basic series of gearbox speeds. The first series is the gear ratio and the second series is the reverse gear ratio.

The layout of the gear axle system in a gearbox relates to its speed ratio. In general, the speed ratio and the centre distance are coupled by the gear axles to form an efficient transmission. Other factors that may affect the layout of the gear axles include space constraints, the axial dimension, and the stressed equilibrium. In October 2009, the inventors of a manual transmission disclosed the invention as No. 2. These gears can be used to realize accurate gear ratios.

The input shaft 4 in the gear housing 16 is arranged radially with the gearbox output shaft. It drives the lubricating oil pump 2. The pump draws oil from a filter and container 21. It then delivers the lubricating oil into the rotation chamber 3. The chamber extends along the longitudinal direction of the gearbox input shaft 4, and it expands to its maximum diameter. The chamber is relatively large, due to a detent 43.

Different configurations of gearboxes are based on their mounting. The mounting of gearboxes to the driven equipment dictates the arrangement of shafts in the gearbox. In certain cases, space constraints also affect the shaft arrangement. This is the reason why the input shaft in a gearbox may be offset horizontally or vertically. However, the input shaft is hollow, so that it can be connected to lead through lines or clamping sets.

Mounting of a gearbox

In the mathematical model of a gearbox, the mounting is defined as the relationship between the input and output shafts. This is also known as the Rotational Mount. It is one of the most popular types of models used for drivetrain simulation. This model is a simplified form of the rotational mount, which can be used in a reduced drivetrain model with physical parameters. The parameters that define the rotational mount are the TaiOut and TaiIn of the input and output shaft. The Rotational Mount is used to model torques between these two shafts.

The proper mounting of a gearbox is crucial for the performance of the machine. If the gearbox is not aligned properly, it may result in excessive stress and wear. It may also result in malfunctioning of the associated device. Improper mounting also increases the chances of the gearbox overheating or failing to transfer torque. It is essential to ensure that you check the mounting tolerance of a gearbox before installing it in a vehicle.

China Standard NMRV RV series hollow shaft reducer copper small worm gear gearbox motor with Free Design Custom

Warranty: 1 year

Model Number: NMRV 30

Usage: NMRV RV series small worm gear gearbox motor

Type: GEAR MOTOR, NMRV RV series small worm gear gearbox motor

Torque: 1.8-1000N.m

Construction: Permanent Magnet

Commutation: Brushless

Protect Feature: Waterproof

Speed(RPM): 14-280rpm

Continuous Current(A): 1-5A

Efficiency: IE 2, 94%~98%

Pole: 1 2 3 4 6 Stage

Ratio: 11-87

Housing Material: Cast Iron

Working temperature: -40~45℃

Application: production equipment soap

Process: Carburizing, Nitriding , Grinding

Mounting Position: Horizontal,Vertical,Flange

Color: Blue,Green,Gray,Red

Certification: NMRV RV series small worm gear gearbox motor

Packaging Details: sea worthy wooden case for NMRV RV series hollow shaft reducer copper small worm gear gearbox motor

YOUR PROFESSIONAL MANUFACTURE

—— SINCE 1995

NMRV Worm Gear Motor Set Reducer Gearbox

TianQi——industrial manufacturers

NMRV RV series small worm gear gearbox motor

Chinese electric motor speed reducer is widely used in mining machinery, chemical industry,steel metallurgy, light industry,environmental protection, paper making, printing, lifting transport, food industry and so on.

Main Series Product: R series helical gear reducer, K series spiral bevel gear reducer, NGW, P series planetary reducer, H B series gearbox, Z (ZDY, ZLY, ZSY, and ZFY) serial hard tooth surface cylindrical gear reducer, D (DBY and DCY) serial hard tooth surface cone gear reducer, cycloid reducer, etc. Meanwhile, map sample processing business can be undertaken.

Specification RV series gearbox reducer worm gear box gear set price for lifting mechanism elevator:

(please contact us for more types & model)

Mounting Diamensions

Model selection for washing machine Gear Box Transmission:

Closely using the ideal reduction ratio.

Reduction ratio = servo motor speed / reducer output shaft speed

Torque calculation: Torque calculation is very important for the life of reducer, and pay attention to whether the maximum torque value (TP) of acceleration exceeds the maximum load torque of the reducer.

The applicable power is usually the applicable power of the servo models on the market, the applicability of the reducer is very high, the working coefficient can be maintained above 1.2, but the choice can also be based on their own needs to decide.H B series standard industrial gear box reducer.Industrial Right Angle Transmission Gearbox price.Gearbox Manufacturer helical gear design gearbox with moderate price. NMRV RV series small worm gear gearbox motor.

Driven machinesWaste water treatmentThickeners,filter presses,flocculation apparata,aerators,raking equipment,combined longitudinal and rotary rakes,pre-thickeners,screw pumps,water turbines,centrifugal pumpsDredgersBucket conveyors, dumping devices, carterpillar travelling gears, bucket wheel excavators as pick up, bucket wheel excavator for primitive material, cutter head, Nylon Rope Pulley Stainless Steel Flat Belt Yumetal CN;SHN Bright Polishment traversing gearsChemical industryPlate bending machines, extruders, dough mills, rubbers calenders, cooling drums, mixers for uniform media, agitators for media with uniform density, toasters, centrifugesMetal working millsplate tilters, ingot pushers, winding machines, cooling bed transfer frames, roller straigheners, table continuous intermittent, roller tables reversing tube mills, shears continuous, casting drivers, reversing CZPT millsMetal working millsReversing slabbing mills. reversing wire mills, reversing sheet mills, reversing plate mill, roll adjustment drivesConveyorsBucket conveyors, hauling winches, hoists, belt conveyors, good lifts, passenger lifts, apron conveyors, escalators, rail travlling gearsFrequency convertersReciprocating compressorsCranesSlewing gears, luffing gears, travelling gears, hoisting gear, derricking jib cranesCooling towersCooling tower fans, blowers axial and radialCane sugar productionCane knives, cane millsBeet sugar productionBeet cossettes macerators, extraction plants, mechanical refrigerators, juice boilers, sugar beet washing machines, sugar beet cutterPaper machinesPulper drivesCablewaysMaterial ropeways, continuous ropewayCement industryConcrete mixer, breaker, rotary kilns, tube mills, separators, roll crushers Technology Feature:

Chinese Speed Reducer is a mechanical transmission in many fields of the national economy. The product categories covered by the industry include all kinds of gear reducer, planetary gear reducer and worm reducer, as well as various special transmission devices such as speed increasing device, speed control Devices, including various types of flexible transmission devices, such as compound transmission. Products and services in the field of metallurgy, nonferrous metals, coal, building materials, ships, water conservancy, electricity, construction machinery and petrochemical industries.

In all fields of national economy and national defense industry, gearbox products have a wide range of applications. Food light industry, electric machinery, construction machinery, metallurgy machinery, cement machinery, environmental protection machinery, electronic appliances, road construction machinery, water conservancy machinery, chemical machinery, mining machinery, conveyor machinery, building materials machinery, rubber machinery, petroleum machinery and other industries have strong demand of Reducer products. NMRV series small gearbox reducer worm gear motor price for lifting mechanism elevator.

Our Services

Packaging & Shipping

Company Information Established in 1995 , HangZhou Boji Machinery is a professional manufacturer and exporter that is concerned with the design, development and production of Gearbox Speed Reducer. We are located in HangZhou of ZheJiang Province, with convenient transportation access. With our own brand “TianQi”, all of our products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world.

Our company possesses complete machining center, lathe, gear shaping machine, gear milling machine, gear grinding machine and assembling lines. Our well-equipped facilities and excellent quality control throughout all stages of production enables us to guarantee total customer satisfaction.

Besides, In 2005,we attained ISO9001 certification. As a result of our high quality products and outstanding customer service, we have gained a global sales network CZPT South America, Saudi Arabia, Vietnam, Pakistan, Philippines, South Africa and other countries and regions.

FAQ

1.Q:Are you the factory or trading company?

A:We are the Factory, with over 25 years of production experience.

2.Q:Can you customize according to our requirements?

A:Yes, we can design nonstandard products according to customer’s drawing and sample.

3.Q:How long is the delivery date?

A:10-20 working days. Cutomized type need to according to the quantity.

4.Q:Where is your factory?

A:We are in HangZhou of ZheJiang Province, you can get here by high speed train or fly to HangZhou.

Welcome to visit us!

5.Q:What’ Helical Gear Reducer Motor Gearbox China Producer s your payment terms?

A:TT 30% as deposite, 70% banlance paid before delivery.

Types of Vehicle Gearboxes

In a vehicle, there are many types of gearboxes available. There are planetary gearboxes, Coaxial helical gearboxes, and skew bevel helical gearboxes, among others. In this article, we’ll cover all of them and help you determine which type of gearbox would be right for your vehicle. Also, we’ll discuss how each differs from the others.

planetary gearbox

A planetary gearbox is composed of three main components: a sun gear, an input bevel gear, and an output shaft. A planetary gearbox can have different output torques and ratios. The basic model of a planetary gearbox is highly efficient and transmits 97% of the power input. There are several kinds of planetary gearboxes, depending on the type of operation. In general, there are three types: the simple, the intermediate, and the complex.

The price of a planetary gearbox can vary a lot, and it’s important to know what you’ll need. Different manufacturers produce different planetary gearboxes, so check with a manufacturer to see what they have available. Make sure to check the quality of the planetary gearbox before making a final purchase. In addition, be sure to compare the prices and the availability of a particular product. A quality planetary gearbox will provide years of trouble-free operation and will not break your bank.

Planetary gears feature an integer number of teeth. Each planet has teeth that must mesh with its ring or sun. The number of planets, ring, and tooth count of each gear determine whether the teeth mesh. Some planets have fewer teeth than others, so they mesh better than others. However, compound planets can be more flexible and achieve higher reduction ratios. If you’re looking for a planetary gearbox for your next project, consider getting in touch with a manufacturer who specializes in this technology.

When it comes to construction, a planetary gearbox is no exception. It’s extremely important to choose the right planetary gear for your application, because an imbalance in the planet gear can cause increased wear and failure. Moreover, the compact size of a planetary gear ensures maximum heat dissipation. However, a planetary gear box may require cooling in some applications. A planetary gearbox will make your life easier, and it will give you years of trouble-free operation.

Straight bevel helical gearbox

The Straight bevel helical gearbox has a number of advantages, but it has a relatively short manufacturing process. Its most popular application is in the automotive industry, where it is used in many types of vehicles. Other applications include heavy and light equipment and the aviation and marine industries. Below is a brief introduction to this gearbox type. Read on to learn about its benefits. This type of gearbox is one of the easiest to manufacture.

The spiral bevel gear has larger teeth than straight bevel gears, resulting in a smoother, quieter rotation. It can handle high-speed heavy loads with less vibration. Spiral bevel gears are classified by their tooth form and cutting method. Straight bevel gears are easier to design and manufacture, but spiral bevel gears are more expensive. Both designs are suitable for high-speed, heavy-load operations, and general manufacturing applications.

In addition to being easy to install, the modular bevel gears have many advantages. They have an exceptionally high degree of interchangeability and feature the highest standards of component integrity. They can also be tailored to meet your specific requirements. The advantages of this gearbox type include high precision, optimum performance, and low noise. And because they are modular, they can be produced in a variety of finishes. These include stainless steel, titanium, and bronze.

Straight bevel helical gearbox manufacturers are committed to a high degree of precision in their designs. The radii, torques, and tooth profiles of straight bevel gears are more precisely measured than those of cylindrical bevel gears. The same calculations are used for all traditional bevel gear generators. This ensures that your 5-axis milled bevel gear sets have the same calculations and layout.

Coaxial helical gearbox

The Coaxial helical gearbox is a highly efficient transmission system that is well suited for light-duty applications. Compared to spur-type gearboxes, the real pitch of a Coaxial helical gearbox is low at all helix angles. This is because the coaxial type has the same number of teeth and center gap as the spur gearbox. Coaxial helical gearboxes also have a smaller footprint and are compact.

Several nations have implemented lockdown regulations for Industrial Gearbox trade, threatening the global economy. Several factors have been implicated in COVID-19, including supply chain, market, and financial markets. Experts are monitoring the situation globally and project remunerative prospects for gearbox manufacturers after the crisis. This report depicts the latest scenario and offers a comprehensive analysis of COVID-19’s impact on the entire industry.

This Coaxial helical gearbox features a compact structure and high precision gear. Its three-stage design combines two-stage gears with a single-stage gear, forging high-quality alloy steel for high precision and durability. The gears are serially-designed for easy interchangeability. They are also available in high-frequency heat-treated steel. A Coaxial helical gearbox is the perfect solution for many applications.

Coaxial helical gearboxes have the added benefit of using cylindrical gears instead of shafts. They operate quietly, and have more surface area to interact with. Their fixed angles make them suitable for heavy-duty applications, like in conveyors, coolers, and grinders. Compared to other gearbox types, Helical gearboxes have higher power-carrying capacity. Listed below are the benefits of a Coaxial Helical Gearbox

Skew bevel helical gearbox

A Skew bevel helical gear box is a common type of industrial gearbox. These gearboxes are rigid and compact and can be used in a variety of applications. They are commonly used in heavy-duty applications such as grinding mills, conveyors, and coolers. They are used in many applications to provide rotary motions between non-parallel shafts. They also have the added benefit of high-efficiency in a variety of industries.

Skew bevel helical gear boxes are suitable for heavy loads and are monolithic in construction. This type of gearbox combines the benefits of bevel and helical gears for right-angle torque, which makes it a popular choice for heavy-duty applications. In addition to being a robust and reliable gearbox, these gearboxes are highly customizable and can meet almost any industrial need.

To maximize the efficiency of bevel gears, FE-based tooth contact analysis is used to develop a sophisticated geometry optimization algorithm. The software also allows users to define optimal flank topography by introducing application-specific weightings for specific load levels. With this data, a manufacturing simulation is conducted to determine the best variant. A robust variant combines the benefits of efficiency, load-carrying capacity, and low excitation behavior.

The helical gear can be angled at 90 degrees. This is similar to a spur gear but produces less noise. It can achieve a nine-to-one speed reduction with one stage. However, a helical gear requires a larger driver gear for higher reductions. This gearbox is suitable for speeds from 1:1 to three times. They are often used in the manufacture of motors and generators.

Extruder helical gearbox

An extruder helical gearbox is one of the most common industrial gears. It is compact in size and low-power consuming, making it ideal for heavy-duty applications. Extruder helical gearboxes are suitable for a variety of industrial applications, including cement, plastics, rubber, conveyors, and coolers. In addition to its use in plastics and rubber manufacturing, this gearbox is also useful in other low-power applications such as crushers, coolers, and conveyors.

CZPT SG series Extruder Helical Gearboxes are available in Single Screw and Twin Screw Variations. These gears feature a compact design, high power density, and long service life. Axial bearing housing and thrust bearings are mounted on the input shafts. Extruder helical gearboxes can be installed in various positions, including horizontal, vertical, and inclined.

Helicoidal gears are often produced in a modular manner. This design provides multiple benefits, including engineering and performance advantages, modular production, and the highest level of component integrity. A single helical gearbox can be assembled into a larger gearbox if needed, but modular production ensures consistent performance and economy. This modular design is also cost-effective. It is a versatile and reliable solution for a wide range of applications.

In addition to its efficiencies, Extruder helical gearboxes also have a low noise profile. They have no squeal sounds, and they are silent when running. They can transfer more power than conventional gearboxes. This type of gear has been used in the manufacturing of high-quality plastic products for years. They are often used for applications in automotive transmissions. Aside from being quiet, helical gears have higher contact levels and lower vibration.

in Gombe Nigeria sales price shop near me near me shop factory supplier Auto Steering Gear Rack Cycle Boxes Motor Pinion Spur Worm Fishing Bevel Hydraulic Camping Tactical Fixed Bike Steering Shift Knob Survival Stainless Steel Gear manufacturer best Cost Custom Cheap wholesaler

More importantly, we make special elements in accordance to equipped drawings/samples and warmly welcome OEM inquiries. Our item range consists of all varieties of helical equipment, spur equipment, bevel equipment, gear rack, worm gear, sprockets,chains, bearings. Additionally, WE CAN Make Tailored VARIATORS, GEARED MOTORS, Electrical MOTORS AND OTHER HYDRAULIC Items According TO CUSTOMERS’ DRAWINGS.

Car steering EPT rack cycle packing containers motor pinion spur worm fishing EPTTl EPT tenting tactical fastened bicycle steering change knob survival stainless steel EPT

in Ikorodu Nigeria sales price shop near me near me shop factory supplier Nmrv Series Iron Housing Reduction 1 7.5 10 15 30 Nmrv110 130 150 Worm Gear Motor Speed Reducer Gearbox manufacturer best Cost Custom Cheap wholesaler

We examine every single piece of bearing by ourselves just before shipping. In 2000, EPG took the direct in getting ISO14001 surroundings administration certificate and thereafter handed the inspection of clear creation and recycling economic climate, successful the title of “Zhejiang Environmentally friendly Business”. Our major merchandise are Needle Roller bearings, Cylindrical Roller Bearings, Rod conclude Bearings, Spherical plain bearings, Monitor roller Bearings for Guideway, Roller Bearings, Mix Bearings for forklifts, Water Pump Bearings, SNR Vehicle Bearings and all kinds of Spherical Bearings.

Solitary Step Worm EPT EPTT.

The EPTT which product is twenty five~ninety manufactured of EPTT alloy die-casting box,excellent looking in visual appeal,compact in construction,rust proofing on surface and modest volume to conserve mounting place.

The EPTT design of one hundred ten~one hundred fifty is made of cast iron which casted with EPTT mould.It`s great seeking and strong, and can be employed through the location of multi-azimuth.

Good radiating characterstic qualified prospects secure and trustworthiness,and high performance for utilizing.

The powerful potential of loading guarantee stable EPTT,make less vibration and sounds.

May differ of connecting composition for EPTT input and torque output fulfill different need-meritsthe style of box outline and the set of foot hole with very good versality is apt to a lot of varieties of mounting.

The merchandise are commonly utilized in the producing equipments of all sorts of EPTT inside and outside EPTT. They are the very best alternatives for nowadaEPTTmodern faXiHu (West EPT) Dis.Hu (West EPT) Dis.ties of mechanical minimizing EPT management to understand large EPTing length, big EPT ratio, small sounds, higher efficiency and stability.

| Model: | NMRV571, 030, 040, 050, 063, 075, 090, 110, a hundred thirty, 150 |

| Ratio: | one:5,7.5,ten,15,20,25,30,forty,50,60,eighty,a hundred |

| EPTT: | EPTT, Silver Or On Client Ask for |

| Sound: | low sound ( lt50DB) |

| Edge: | Effective and risk-free functioning |

|

EPT: |

EPT: Die-Forged EPTT Alloy |

| Worm EPT-Bronze 9-4# | |

| Worm-20CrMnTi with carburizing and quenching, floor harness is fifty six-62EPTC | |

| Shaft-chromium steel-forty five# | |

| EPTT: | EPTT and EPTen Circumstance |

| EPTT: | C ampU EPTT |

| Seal: | NAK SKF |

| Certification: | ISO9001,CE,3C,OEM |

| Warranty: | twelve months |

| Input EPTT: | .06kw, .09kw, .12kw, .18kw, .25kw, .37kw, .55kw, .75kw, 1.1kw, one.5kw, 2.2kw, 3kw, 4kw, 5.5kw, seven.5kw, 11kw, 15kw |

| Usages: | EPTT EPTT: Foods Stuff, EPTT,EPTT,EPTT,Dyeing, EPTworking,Glass. |

| IEC Flange: | 56B5, 56B14, 63B5, 63B14, 71B5, 71B14, 80B5, 80B14, 90B5, 90B14, 100B5, 100B14, 112B5, 112B14, 132B5, 160B5 |

| Lubricant: | Artificial amp Mineral |

Our manufacturing facility and in stock:

We are the resource manufacturing unit, so we can customize our goods in accordance to the demands of our clients and hope to EPT your letter.

Our assure:

FAQ:

Q1: Are you investing business or company ?

A: We are a manufacturer in EPTTngsu EPTT.welcome to our manufacturing facility to have a visit.

Q2: How we select versions and specs?

A:You can e-mail us the series title amp code (for illustration: WJ series worm EPTT) as nicely as necessity details, such as motor EPTT, output velocity or ratio, provider element or your application…as significantly knowledge as attainable. If you can provide some pictures or drawings, it is EPT.

Q3: How is your value? Can you offer any discount?

A: We will give the ideal price tag we can base on your wants and the quantities.

This autumn: How EPTT must I hold out for the suggestions following I deliver the enquiry?

A: In 12 hours.

Q5: What is your product warranty period?

A:We supply a single year warranty since the vessel departure date still left EPTT.

Q6: What EPTT are your EPTTes getting used?

A:Our EPTTes are commonly applied to metallurgical products, mining tools, EPTT tools, foodstuff EPTTry, EPTT equipment, tobacco products and so on.

We are looking EPTT to your letter and inquiry. You are welcome to occur to EPTT for inspection at any time:

in Dakar Senegal sales price shop near me near me shop factory supplier 88zyt 24volt DC Worm Gear Motor for Automatic Machine manufacturer best Cost Custom Cheap wholesaler

If you need to have any details or samples, remember to make contact with us and you will have our quickly reply. Ever-Power Group CO., LTD. IS Professional IN Generating ALL Kinds OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Equipment Speed REDUCERS, PARALLEL SHAFT HELICAL Equipment REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Equipment REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Auto GEARBOXES, PTO Travel SHAFTS, Unique REDUCER & Connected Gear Factors AND OTHER Related Goods, SPROCKETS, HYDRAULIC Technique, VACCUM PUMPS, FLUID COUPLING, Gear RACKS, CHAINS, TIMING PULLEYS, UDL Velocity VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Gear PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Minimal BACKLASH WORM REDUCERS AND SO ON. We have exported our items to Korea, Turkey, Bulgaria, Romania, Russia, Italy, Norway, the United states of america, Canada, and so forth.

Fundamental Info.

Model NO.:D88R

Item No.:Wiper EPTT

Nominal EPTT:50W

Solution Description

24V DC WORM Gear MOTOR FOR Vehicle

one. It haves EPTT utilization time

two. Little QTY acknowledged

three. Very good reputation and large good quality in the domestic market

four. Good soon after-sale service and samply is obtainable,freigEPTT EPTT

five.Software for town bus, journey bus, mentor.

EPTT Element: StXiHu (West Lake) Dis.Hu (West Lake) Dis.rd export carton

Service: good soon after-sale provider and samply is offered, freigEPTT EPTT

Certification:CCC, CE

| Design | Voltage | EPTT | No-load velocity | No-load existing | Rated velocity | Rated current | Rated torque | Ratio |

| V | W | rpm | A | rpm | A | N.m | ||

| D88R-36100-20 | 36 | 100 | 20 plusmn2 | le2.5 | 16 plusmn2 | le5.5 | ge5.5 | 1:82 |

| D88R-28200-200 | 28 | 200 | 200 plusmn5 | le2.5 | 185 plusmn5 | le6. | ge5. | 1:34 |

| D88R-24150-a hundred and eighty | 24 | a hundred and fifty | one hundred eighty plusmn5 | le2. | 185 plusmn5 | le6. | ge5. | one:34 |

| D88R-12120-a hundred | twelve | a hundred and twenty | one hundred plusmn5 | le3.two | 95 plusmn5 | le8. | ge4.5 | one:34 |

two.Creation Stream

In recent 10 a long time, EPTTry has been committed to the manufacture of the motor merchandise and the main products can be classified into the adhering to sequence, specifically DC motor, DC EPTT motor, AC motor, AC EPTT motor, Stepper motor, Stepper EPTT motor, Servo motor and EPTT actuator series.

Our motor merchandise are broadly applied in the fields of aerospace business, automotive sector, finXiHu (West Lake) Dis.Hu (West Lake) Dis.al gear, EPTT EPTT, EPTT EPTT and robotics, medical equipment, workplace equipment, EPTT EPTTry and EPTT sector, providing consumers reliable personalized answers for driving and controlling.

four.Our Solutions

one). EPTT Provider:

| Fast Reply | All enquiry or e-mail be replied in 12 several hours, no delay for your organization. |

| Expert Crew | Queries about goods will be replied skillfully, just, very best suggestions to you. |

| Short EPTT time | Sample or small orEPTTsent in 7-fifteen days, bulk or EPT orEPTTabout 30 times. |

| Payment Choice | T/T, Western EPT,, L/C, and so forth, effortless for your enterprise. |

| Just before shipment | EPTTke photographs, deliver to consumers for affirmation. Only confirmed, can be delivered out. |

| Language Option | Besides EPTT, you can use your own language by e-mail, then we can translate it. |

2). Customization Support:

EPTT specification(no-load velocity , voltage, torque , diameter, noise, life, tests) and shaft length can be tailor-created according to customer’s demands.

5.Deal amp EPTT

6.Get in touch with Information

Rachel Ye

————————————-

HangEPTT EPTTry E ampM Tech. Co., Ltd.

China manufacturer & factory supplier for NMRV090 in Meerut India series wps worm gear speed reducer motor hollow shaft motor speed variator bevel helical gearbox With high quality best price & service

Our large inventory levels on zinc plated, solid steel shaft collars guarantee prompt gratification of any measurement prerequisite. Unplated, black-oxide and stainless metal strong collars are easily obtainable. Black-oxide steel clamp type collars are in the same way stocked for unbeatable service. Mounted bearing and linear bearing orders are routinely delivered in 24 hrs and our change-around time on cut-to-duration linear shafting will exceed your anticipations.EPG has been efficiently certified by ISO9002 Good quality Administration Technique, ISO9001 Quality Management Method, API certificate, ISO/TS16949:2002 and ISO10012 measurement administration method.

Overview

Rapid Particulars

- Relevant Industries:

-

Building Content Shops

- Gearing Arrangement:

-

Worm

- Output Torque:

-

4~2320Nm

- Enter Velocity:

-

.28~4.7rpm

- Output Speed:

-

1400rpm(4pole)

- Spot of Origin:Zhejiang, China

- Model Identify:

-

OEM

- Label:

-

Customer requirement

- Enter Flange:

-

IEC flange for mounting motor

- Top quality Management Program:

-

ISO9001:2008

- Substance of housing:

-

Aluminum&Cast Iron

Supply Capacity

- Without sufficient venting, high temperatures increase inner stress which can power lubricant previous seal lips or increase lip contact force, accelerating seal wear and grooving on the seal journals. Offer Capability:

- 20000 Set/Sets for every Month

Packaging & Supply

- Packaging Information

- Carton + Picket Case

- Port

- Shanghai/Ningbo port

On-line Customization

NMRV090 series wps worm equipment pace reducer motor hollow shaft motor speed variator bevel helical gearbox

Item Description

1. Mad of substantial-good quality aluminum alloy,gentle weight and non-rusting

2. Massive output torque

three. Sleek in managing and reduced in sound,can work long time in dreadful problems.

4. Large in radiating effectiveness.

5. Excellent-lookEPG manufacturer rotocultivator ploughshares in T. line had been selected as the Nationwide Rotary Tillage Machinery Sector “Excellent Model Merchandise” in 2007 by Rotocultivator Branch of China Agricultural Equipment Industry Association. ing in physical appearance,resilient in services daily life and modest in quantity.

6. Suited for omnibearing installation.

|

Variety: |

Worm Gear Speed Reducer/ Gearbox |

|

Design No.: |

NMRV025, NMRV030, NMRV040, NMRV050, NMRV063, NMRV075, NMRV090, NMRV110, NMRV130, NMRV150 |

|

Ratio: |

five,7.5,ten,fifteen,twenty,25,30,forty,fifty,sixty,eighty,100 |

|

Coloration: |

Blue(Ral5010)/Silver Gray (RAL9006) Or On Client Request |

|

Content: |

Housing: Dimensions 25-a hundred and ten Is Aluminum Alloy, Dimensions 110-150 Is Solid-Iron |

|

Worm Wheel: ZCuSn10Pb1 |

|

|

Worm:20Cr |

|

|

Pinion:Tin Bronze |

|

|

Output Shaft: Steel-forty five# |

|

|

Usages: |

Industrial Device: Meals Stuff, Ceramics, Chemical, Packing, Dyeing,Wooden working, Glass. |

|

IEC Flange: |

IEC Normal Flange Or On Consumer Ask for |

Company Data

Certifications

Our Companies

Packaging & Shipping and delivery

PTO Adapters To steer clear of possible connectivity problems, you could want to consider a PTO Adapter for your tractor. The PTO adapter extends the connection to the employ, supplying added space for the PTO shaft to turn without touching the Arm Weldment or other parts of your tractor or the put into action.

FAQ

: Are you trading business or company ?

A: We are manufacturing facility.

Q: How extended is your supply time?

A: Usually it is 5-ten days if the merchandise are in inventory. or it is 15-20 times if the merchandise are not in stock, it is according to quantity.

Q: Do you offer samples ? is it totally free or extra ?

A: Yes, we could offer the sample for cost-free charge but do not pay the value of freight.

Q: What is your conditions of payment ?

A: Payment=1000USD, thirty% T/T in advance ,harmony ahead of shippment.

If you have an additional question, pls come to feel totally free to contact us as under:

Get in touch with us