Product Description

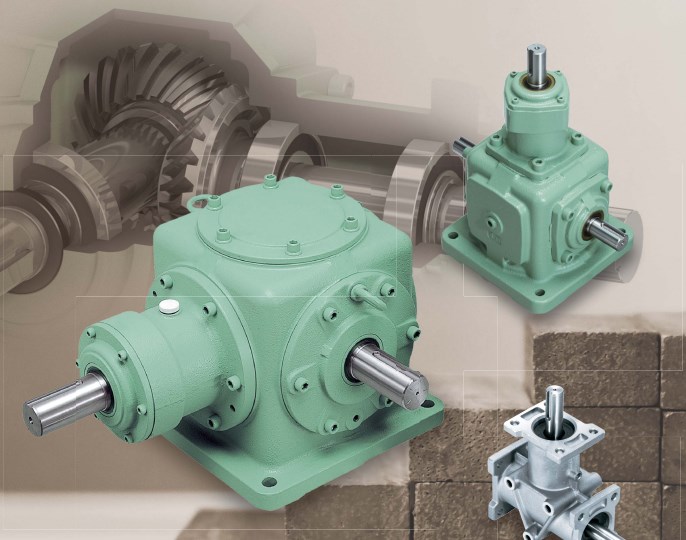

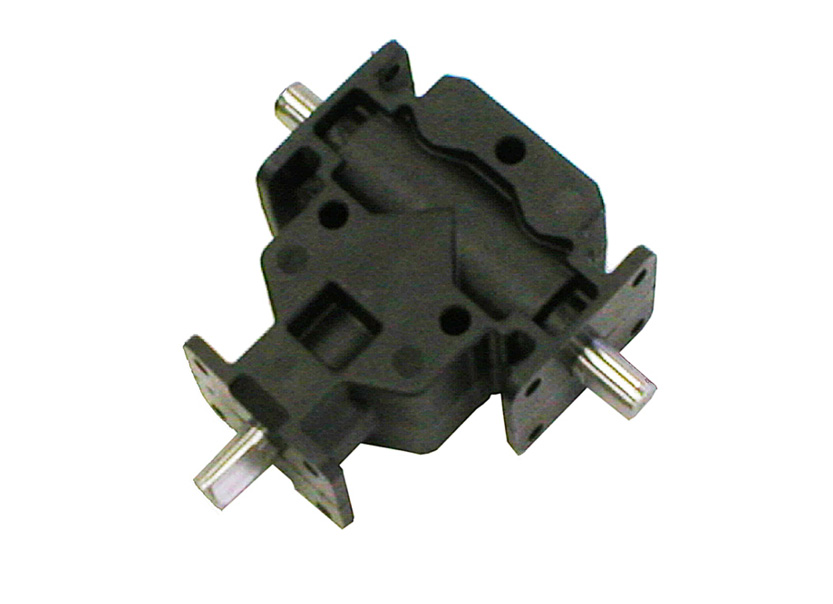

Miter gear boxes are made from lightweight aluminum and resists corrosion. Their rigid gear design includes internal bearing support elements. In addition, stainless steel shafts provide resistance to corrosion and spiral bevel gearing allows higher operating speeds. These units are lubricated for life to assure trouble free service. Their design includes universal mounting options 5 surfaces) for maximum design flexibility. Miter gear boxes are constructed with rugged iron housings. They provide rigid gear and substantial internal bearing support. Additionally, tapered roller bearings increase their endurance and strength. Double lip, spring loaded seals keeps lubricant in and dirt out.

How Does A Compact and Lightweight Gearbox Work?

Corrosion Resistant Aluminum Alloy Bevel Gearboxes Videos For Customers Orders

* Indonesia customer Lightweight aluminum housing Small-sized Mini right angle drive 1:1 gearboxes Video:

* Canada clients miniature right angle bevel gearboxes 1:1 ratio/small right angle gear drives Video:

* Lithuania client 1:1 ratio JTA15 lightweight small aluminium miniature right angle gearbox Video:

* Colombia client light duty aluminum bevel gear box 1 to 1 ratio,aluminum body gearbox 3 shafts Video:

* Belgium client lightweight aluminum alloy right 90 spiral bevel gear drives gearbox 1:1 ratio Video:

* Israel customer 3 shaft gearboxes 1:1 ratio 3 way bevel gear boxes 20mm shafts 90 deg gearbox Video:

* 16567X3, registered Capital 500000CNY) is a leading manufacturer and supplier of Screw Jacks (Mechanical Actuators), Bevel Gearboxes, Lifting Systems, Electric Linear Actuators, Gearmotors and Speed Reducers, and Others Linear Motion and Power Transmission Products in China. We are Alibaba, Made-In-China and SGS (Serial NO.: QIP-ASI192186) audited manufacturer and supplier. We also have a strict quality system, with senior engineers, experienced skilled workers and practiced sales teams, we consistently provide the high quality equipments to meet the customers electro-mechanical actuation, lifting and positioning needs. CZPT Industry guarantees quality, reliability, performance and value for today’s demanding industrial applications.

Website (English): screw-jacks

Website (English): screw-jacks

Website (Chinese): screw-jacks

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Agricultural Machinery, Car, Metrology and Test Engineering |

|---|---|

| Function: | Distribution Power, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase, Transmission |

| Layout: | Right Angle Drive |

| Hardness: | Hardened Tooth Surface |

| Installation: | Universal Mounting |

| Step: | Single-Step |

Distinguishing Miter Gearboxes from Other Types of Gear Systems

Miter gearboxes possess distinct characteristics that set them apart from other types of gear systems, making them suitable for specific applications:

1. Angular Motion Transmission: Miter gearboxes excel at transmitting motion at a precise angle, typically 90 degrees, between intersecting shafts. This is achieved through the use of bevel gears with matching angles on their teeth.

2. Compact and Space-Saving Design: Miter gearboxes have a compact form factor, making them ideal for applications with limited space. Their right-angle configuration allows them to efficiently change the direction of motion without requiring additional components.

3. High Efficiency: Due to their precision machining and careful design, miter gearboxes offer high efficiency in transmitting power between intersecting shafts. They minimize backlash and friction, resulting in smooth and efficient motion transfer.

4. Wide Range of Applications: Miter gearboxes find use in various industries, including automotive, robotics, machinery, and more. Their ability to redirect motion and transmit power at right angles makes them versatile for different mechanical systems.

5. Backlash Minimization: Miter gearboxes are designed to minimize backlash through precise tooth profile shaping, gear alignment, and high-quality bearings. This ensures accurate and reliable motion without unwanted play.

6. Specialized Applications: While other gear systems like helical or spur gears offer advantages in certain scenarios, miter gearboxes excel in applications requiring angular transmission, compactness, and efficient power transfer at right angles.

Overall, miter gearboxes stand out for their unique ability to transmit motion at a specific angle and their compact, efficient, and versatile design, making them a valuable choice for a range of mechanical applications.

| Customization: |

Available

| Customized Request |

|---|

Handling High Torque and Speed Requirements with Miter Gearboxes

Miter gearboxes are versatile mechanical components that can be designed to handle both high torque and speed requirements, making them suitable for a wide range of applications.

The ability of miter gearboxes to handle high torque is determined by factors such as the quality of the gear materials, the precision of gear teeth profiles, and the design of the gearbox itself. Miter gearboxes can be engineered with robust and durable materials, optimized gear tooth profiles, and advanced lubrication systems to ensure effective torque transmission without excessive wear or failure.

Similarly, miter gearboxes can be tailored to accommodate high-speed applications. Proper selection of gear materials, lubrication, and design considerations, such as gear tooth geometry and bearing arrangements, contribute to minimizing friction, heat generation, and wear at elevated speeds.

It’s important to note that while miter gearboxes can handle both high torque and speed, there may be practical limitations based on the specific design, size, and intended use of the gearbox. Engineers and designers carefully assess the torque and speed requirements of the application to ensure that the miter gearbox is appropriately designed and configured for optimal performance and longevity.

editor by CX 2023-08-30