Product Description

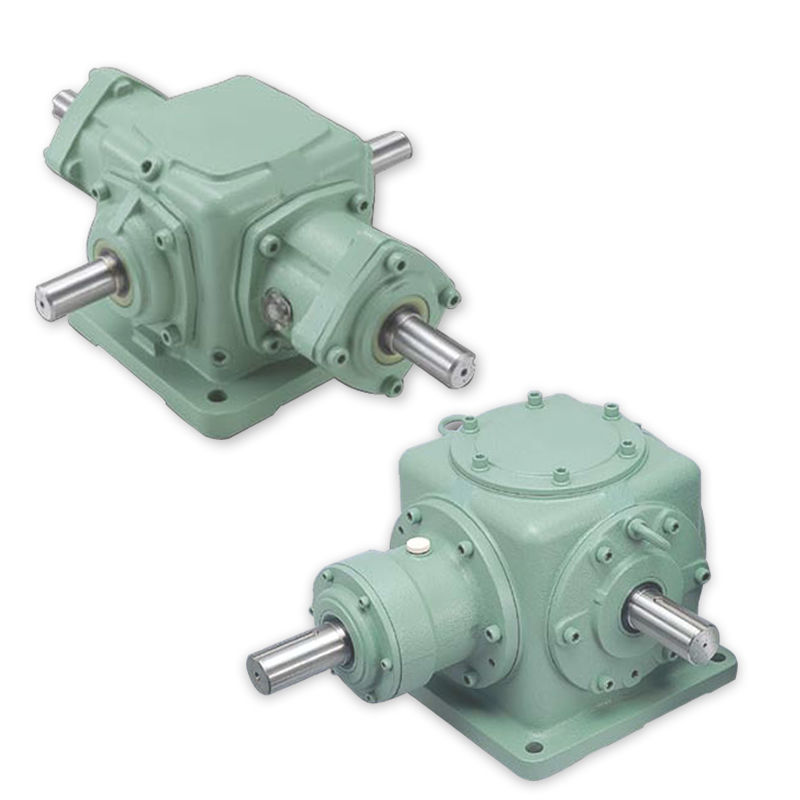

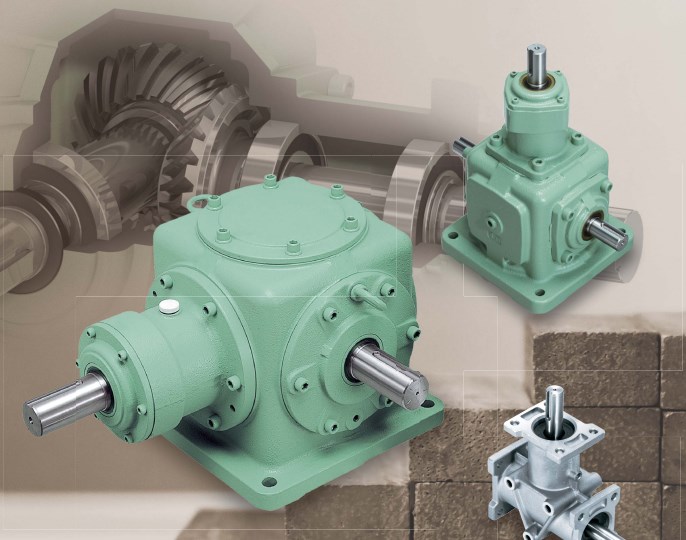

T series high precision reductor spiral bevel gearbox for packing machine

Product Description

Technical data:

1. Power: 0.37-200 (KW)

2. Output Speed: 11-226RMP,

3. Torque: 400-56000 (N. M)

4. Transmission stage: Three stage

Applications:

The products are widely applied in electricity, coal, cement, metallurgy, harbor, agriculture, shipping, lifting, environment protection, stage, logistic, weaving, paper making, light industry, plastics and other regions

1. We accept sample order.

2. We undertake the problems due to quality.

3. We supply detail answers about technical questions.

4. We are the manufacturer so we could supply the products as soon as possible.

5. At the instance of our dear customer, we can do the customized gear boxes for clients.

Detailed Photos

Commercial information:

1. MOQ: 1 set

2. Packing method: Polywood

3. Delivery lead time: 10-25 days

4. Price terms: FOB, CIF, EXW

5. Payment method: T/T, 30% in advance, 70% balance before delivery

6. Shipping port: HangZhou

7. OEM: We accept customized products as per your special requirement.

8. Xihu (West Lake) Dis.lines for the Selection: Usually we can select 1 machine which is suitable for you with some informations from you, such as ratio/motor speed/mounting dimension/ output torque etc.

9. If the minimum order amount is in excess of $10000, there are preferential

| input power | 0.018-96kw |

| ratio | 1-3 |

| permissable torque | 11-607N.M |

| mounting type: | footmounted |

| usage: | change direction |

Product Parameters

| Models | Input Power | Ratio | Max. Torque | Weight(kg) | Output Shaft Dia.(k6) |

| T2 | 0.014KW~1.79KW | 1~2 | 11 | 2 | Φ15 |

| T4 | 0.026KW~4.94KW | 1~2 | 31 | 10 | Φ19 |

| T6 | 0.037KW~14.9KW | 1~3 | 94 | 21 | Φ25 |

| T7 | 0.042KW~22KW | 1~3 | 139 | 32 | Φ32 |

| T8 | 0.064KW~45.6KW | 1~3 | 199 | 49 | Φ40 |

| T10 | 0.11KW~65.3KW | 1~3 | 288 | 78 | Φ45 |

| T12 | 0.188KW~96KW | 1~3 | 607 | 124 | Φ50 |

| T16 | 0.40KW~163KW | 1~3 | 1073 | 188 | Φ60 |

| T20 | 0.69KW~234KW | 1~3 | 1943 | 297 | Φ72 |

| T25 | 1.4KW~335KW | 1~3 | 3677 | 488 | Φ85 |

Ratio: 1:1, 1.5:1, 2:1, 2.5:1, 3:1

Packaging & Shipping

Company Profile

After Sales Service

| Pre-sale services | 1. Select equipment model. |

| 2.Design and manufacture products according to clients’ special requirement. | |

| 3.Train technical personal for clients | |

| Services during selling | 1.Pre-check and accept products ahead of delivery. |

| 2. Help clients to draft solving plans. | |

| After-sale services | 1.Assist clients to prepare for the first construction scheme. |

| 2. Train the first-line operators. | |

| 3.Take initiative to eliminate the trouble rapidly. | |

| 4. Provide technical exchanging. |

FAQ

FAQ:

1.Q:What kinds of gearbox can you produce for us?

A:Main products of our company: UDL series speed variator,RV series worm gear reducer, ATA series shaft mounted gearbox, X,B series gear reducer,

P series planetary gearbox and R, S, K, and F series helical-tooth reducer, more

than 1 hundred models and thousands of specifications

2.Q:Can you make as per custom drawing?

A: Yes, we offer customized service for customers.

3.Q:What is your terms of payment ?

A: 30% Advance payment by T/T after signing the contract.70% before delivery

4.Q:What is your MOQ?

A: 1 Set

Welcome to contact us for more detail information and inquiry.

If you have specific parameters and requirement for our gearbox, customization is available.

| Application: | Machinery, Industry |

|---|---|

| Function: | Change Drive Direction, Speed Reduction |

| Layout: | Right Angle |

| Hardness: | Hardened |

| Installation: | Vertical Type |

| Step: | Single-Step |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Minimizing Backlash and Ensuring Efficient Power Transfer in Miter Gearboxes

Miter gearboxes are meticulously designed to minimize backlash and ensure efficient power transfer, contributing to smooth and reliable operation in various mechanical systems.

Backlash, the slight movement or play between mating gears, can lead to imprecise motion and reduced accuracy. To address this, miter gearboxes incorporate features such as precision-machined gear teeth, high-quality bearings, and precise alignment of gears and shafts. These design elements help minimize the clearance between gear teeth, reducing or eliminating backlash and ensuring consistent motion transfer.

Efficient power transfer in miter gearboxes is achieved through careful consideration of gear geometry, tooth profiles, and material selection. Engineers optimize gear tooth shapes to minimize friction and maximize contact area between mating gears. Additionally, high-quality materials with appropriate hardness and surface finish are chosen to enhance durability and reduce energy losses due to friction.

The lubrication system also plays a critical role in efficient power transfer. Proper lubrication reduces friction, dissipates heat, and prevents wear, contributing to the overall efficiency of the gearbox.

Overall, the design of miter gearboxes focuses on tight tolerances, precision manufacturing, and thoughtful engineering to minimize backlash and maximize power transfer efficiency, resulting in reliable and high-performance mechanical systems.

Limitations of Torque and Speed in Miter Gearboxes

Miter gearboxes, like any mechanical component, have certain limitations when it comes to handling torque and speed. These limitations are influenced by factors such as design, materials, and manufacturing processes:

- Torque Capacity: The maximum torque that a miter gearbox can handle is determined by the size and strength of the gears, shafts, and housing. Exceeding the rated torque can lead to gear tooth wear, tooth breakage, and even gearbox failure.

- Speed Limitations: The rotational speed of a miter gearbox is limited by factors like the diameter of the gears and the quality of the gear teeth. High speeds can generate heat and cause excessive wear, reducing the lifespan of the gearbox.

- Heat Generation: Excessive torque or speed can lead to increased heat generation due to friction and load. Elevated temperatures can affect the lubrication, material strength, and overall performance of the gearbox.

- Lubrication: Inadequate or improper lubrication can limit the torque and speed capabilities of a miter gearbox. Lubrication helps reduce friction and dissipate heat, enabling the gearbox to handle higher loads and speeds.

- Material Strength: The choice of materials used in the gearbox’s construction influences its torque and speed limitations. High-quality materials with appropriate hardness and tensile strength are essential for withstanding heavy loads and high speeds.

It’s important to carefully consider the specific torque and speed requirements of an application when selecting a miter gearbox. Exceeding the gearbox’s rated limits can result in decreased performance, increased wear and tear, and potential system failures.

Transmission of Motion in Miter Gearboxes

Miter gearboxes transmit motion at an angle between intersecting shafts through the use of bevel gears with perpendicular axes. These bevel gears have teeth that are cut at a 45-degree angle to the gear’s face and mesh with each other. When one bevel gear is rotated, its teeth engage with the teeth of the other bevel gear, resulting in torque transfer and motion redirection at a 90-degree angle.

As the input shaft turns the first bevel gear, its teeth push against the teeth of the second bevel gear. This interaction causes the second bevel gear to rotate around its perpendicular axis, transferring motion to the output shaft. The gear ratio and the number of teeth on each gear determine the speed and torque characteristics of the transmitted motion.

Due to their ability to redirect motion while maintaining efficient power transmission, miter gearboxes are commonly used in applications where a change in direction is necessary, such as in steering systems, printing machinery, and other mechanical systems requiring precise angular alignment.

editor by CX 2023-09-18