Product Description

Product Description

factory hot sale CHINAMFG J40/40 53KW-61KW used for china vessel boat ship marine engine gearbox

| 40A Modle | ||

| Feature | Fluid control, price favorable | |

| Housing:SAE 1.2.3 | Flange:111/2″,14″ | |

| L×W×H: | 750×590×720mm | N.W.240kg |

| NOMINAL RATIO | EXACT RATIO | RATE(HP/RPM) |

| 2:01 | 2.066:1 | 0.04 |

| 3:01 | 2.957:1 | 0.04 |

| Recommended engine:YANMAR 6CHLN; BAUDOUIN 4D 106 | ||

| 120B Modle | ||

| Feature | Compact structure, fluid control | |

| Housing:SAE 1 | Flange:14″ | |

| L×W×H: | 720×850×870mm | N.W.360kg |

| Nominal coefficient | Accurate coefficient | Ratio (horsepower/r/m) |

| 2:01 | 2.571:1 | 0.12 |

| 3:01 | 2.815:1 | 0.12 |

| Recommended engine | CUMMINS N-885-M;CAT.3306B SCAC.;DAF DKVD1160M;DETROIT 6V-92TA YANMAR 6HA(M)-HTE | |

Advantage Products

Company Profile

Packaging & Shipping

Contact us

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Applicable Industries: | Marine Engine |

|---|---|

| Output Speed: | 2000rpm |

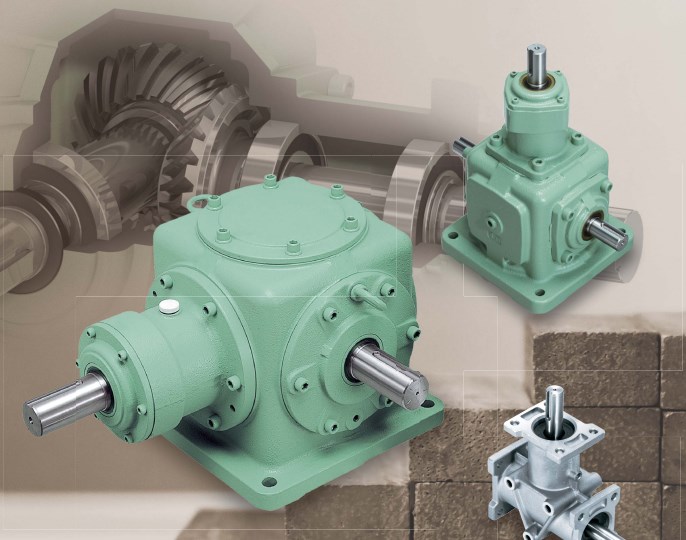

| Gearing Arrangement: | Bevel / Miter |

| Input Speed: | 750rpm |

| Net Weight: | 230kg – 232kg |

| Product Name: | Fada J40/40 53kw-61kw Used China Marine Gearbox |

| Customization: |

Available

| Customized Request |

|---|

Performance of Miter Gearboxes in Applications Requiring Precise Angle Changes

Miter gearboxes excel in applications that demand precise angle changes in motion transmission. Their ability to efficiently and accurately redirect rotational motion by 90 degrees makes them ideal for tasks where precise angular positioning is essential. Industries such as robotics, automation, machinery, and manufacturing often utilize miter gearboxes to achieve accurate and repeatable angular changes, ensuring proper alignment and movement of components. The compact and space-saving design of miter gearboxes further enhances their suitability for applications that require tight spatial constraints and precise motion control.

Efficient Power Transmission and Torque Transfer with Miter Gearboxes

Miter gearboxes play a crucial role in ensuring efficient power transmission and torque transfer in mechanical systems. Here’s how they contribute:

- Optimal Gear Meshing: Miter gearboxes are designed with precision-cut bevel gears that mesh seamlessly, minimizing energy losses and ensuring a high degree of power transfer efficiency.

- Angular Transmission: These gearboxes excel at transmitting rotational motion at specific angles, allowing torque to be efficiently redirected or transferred between intersecting shafts.

- Multiple Gear Meshes: Miter gearboxes often have multiple gear meshes, distributing torque and load evenly across the gears, reducing wear and enhancing overall efficiency.

- Compact and Sturdy Design: The compact construction of miter gearboxes reduces the distance between shafts, minimizing flex and misalignment that could lead to power losses.

- High-Quality Materials: Miter gearboxes are constructed from durable materials that can withstand high torque and load, ensuring reliable power transmission over extended periods.

- Smooth Motion Transfer: The bevel gears in miter gearboxes facilitate smooth and uniform motion transfer, reducing vibration and minimizing energy dissipation.

- Minimal Backlash: Properly designed miter gearboxes have minimal backlash, ensuring that torque is efficiently transmitted without significant play or lost motion.

Overall, miter gearboxes optimize power transmission and torque transfer, making them suitable for applications that demand efficient and reliable angular motion conversion and redirection.

Handling High Torque and Speed Requirements with Miter Gearboxes

Miter gearboxes are versatile mechanical components that can be designed to handle both high torque and speed requirements, making them suitable for a wide range of applications.

The ability of miter gearboxes to handle high torque is determined by factors such as the quality of the gear materials, the precision of gear teeth profiles, and the design of the gearbox itself. Miter gearboxes can be engineered with robust and durable materials, optimized gear tooth profiles, and advanced lubrication systems to ensure effective torque transmission without excessive wear or failure.

Similarly, miter gearboxes can be tailored to accommodate high-speed applications. Proper selection of gear materials, lubrication, and design considerations, such as gear tooth geometry and bearing arrangements, contribute to minimizing friction, heat generation, and wear at elevated speeds.

It’s important to note that while miter gearboxes can handle both high torque and speed, there may be practical limitations based on the specific design, size, and intended use of the gearbox. Engineers and designers carefully assess the torque and speed requirements of the application to ensure that the miter gearbox is appropriately designed and configured for optimal performance and longevity.

editor by CX 2024-05-09