Product Description

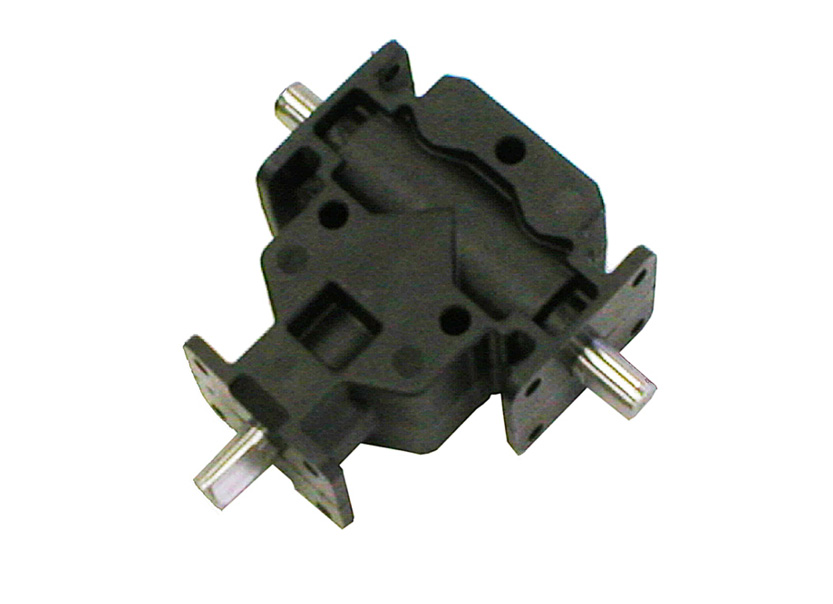

EP-01-674 Gearbox Aluminum Box Series for Agricultural

features

The aluminum gearbox series is designed for heavy industrial applications and is ideal for various gearboxes.

Industry. Its low maintenance cost, CHINAMFG structure, and long service life make it an ideal choice for various products.

Application. Understand how these transmissions work in the following industries. These gearboxes weigh only a few pounds, are durable, and have low maintenance costs.

Gearboxes are used in many industries

In addition to being an essential machinery component, gearboxes are also used in many other industries. These devices are used to increase torque and, in some cases, to reduce speed. They come in many types and can be customized to meet specific requirements. For example, the paper industry relies heavily on industrial machinery, including custom gearboxes. Here are some industries that use gearboxes:

The automobile gearbox is made of aluminum alloy. Aluminum alloys for gearboxes have a high strength-to-weight ratio. It also has excellent corrosion, wear, and thermal conductivity. The main advantages of an aluminum alloy gearbox are its high strength-to-weight ratio, low density, good thermal conductivity, and attractive appearance. For gearbox manufacturing, these alloys are usually die-cast or machined.

They are low maintenance

The aluminum gearbox series has the advantages of reducing wear and high durability. These gears are designed with spiral bevel gears, which are light and durable. The gear is also lubricated with synthetic oil, with long service life. The miter gear of ket motion 2571 is designed for high-speed and low-noise transmission operation. The high-precision design of the gearbox provides 9 decelerations per tooth and has a high-strength aluminum alloy shell.

They are solid

The transmission aluminum box series is designed and manufactured with high-strength aluminum alloy. The structure of these gearboxes is complex, with a concave-convex structure and a side core pulling mechanism. The main component of the alloy is alsi9cu3, which is used for high-strength aluminum alloy gear cases. These gearboxes’ chemical composition and mechanical properties are also of the highest quality. A high-pressure point cooling plug-in is set on the slide block or side slide block to improve the speed of the cooling position.

|

ITEM |

EP-01-674 |

|

Ratio |

1.46:1 |

|

Teeth |

19/13 |

|

Module |

5 |

|

Power(HP) |

23 |

|

Rated Input |

540 rpm |

|

Input/Output Description |

13/8 Z6 |

|

Weight(N.W) |

7.2Kg |

We Also Supply PTO Shaft

other gearboxes

Agricultural Gearbox Production Workshop

Ever-power is a professional agricultural machine gearbox manufacturer. It produces more than 1,000 kinds of products and supports OEM and ODM. Including lawn mower series, rotary tiller series, rice harvester series, grain transportation storage series, etc. Has been exported to numerous countries like America, Australia, India, Poland, etc. We work with CHINAMFG brands like John Deere, Bush Hog, etc. Our annual production is 300,000 units, and our turnover in 2571 is USD 28 million. The export ratio is 80%, and the domestic market is 20%.

HangZhou Ever-power Transmission Machinery Co., Ltd. was established in 2006. The company is located in ZHangZhoug HangZhou, with 90 employees, an area of 3800 meters, and an annual output value of 40 million yuan. The company is committed to the R & D, manufacturing, and personnel training of various gearboxes, reducers, and construction machinery, including spiral bevel gearbox, spur gearbox, worm gearbox, and cylindrical gearbox. It also includes a variety of high-pressure cast valve body and shell products. Its products are used in various applications, such as agricultural mowers, snow sweepers, fertilizer applicators, grain conveyors, industrial equipment, oil mining machinery, marine industrial equipment, and hydraulic engineering components. More than 95% of its products are exported to Europe, the United States, and Australia. Asia and Canada. The company has robust technology and R & D capabilities, produces reliable and high-quality products, pursues a unique business philosophy, and enjoys a high reputation in the manufacturing industry. Welcome to contact us by phone or email.

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Type: | Agricultural Gearbox |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

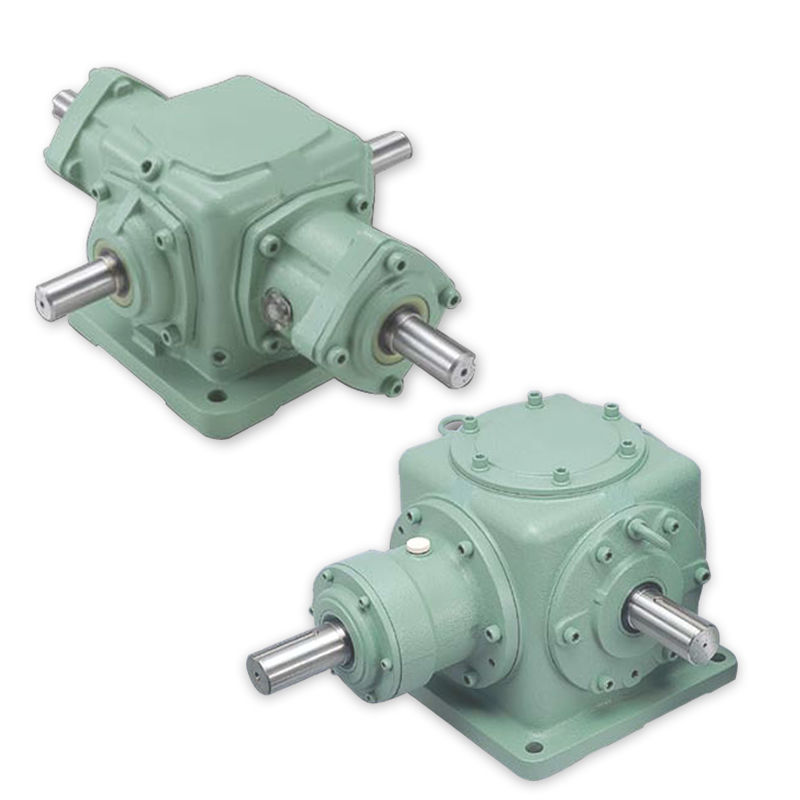

Role of Miter Gearboxes in the Automotive Manufacturing Process

Miter gearboxes play a significant role in the automotive manufacturing process, contributing to various aspects of vehicle production. One of their primary functions is in the assembly and adjustment of automotive components that require precise angle changes.

Automotive manufacturing involves the production of parts and assemblies with specific angles and orientations. Miter gearboxes are used in assembly line machinery to accurately position components such as axles, suspension systems, steering columns, and drivetrain elements. By allowing controlled and precise angular adjustments, miter gearboxes ensure that these components are aligned correctly and securely fitted together.

Furthermore, miter gearboxes find application in robotic systems used for tasks like welding, painting, and material handling in automotive manufacturing. They enable robots to manipulate tools and parts at precise angles, contributing to the accuracy and quality of manufacturing processes.

In summary, miter gearboxes contribute to the efficiency, accuracy, and quality of various processes within the automotive manufacturing industry, helping to produce vehicles that meet stringent quality standards and performance requirements.

Key Benefits of Using Miter Gearboxes in Angular Transmission Applications

Miter gearboxes offer several key benefits when used in applications requiring angular transmission:

- Precise Angle Transmission: Miter gearboxes excel at transmitting rotational motion at specific angles, ensuring accurate and controlled angular adjustments.

- Compact Design: Their compact and space-saving design allows for efficient integration into machinery and equipment with limited space.

- High Efficiency: Miter gearboxes are engineered for efficient power transmission, minimizing energy losses during angular motion transfer.

- Smooth Operation: The meshing of bevel gears in miter gearboxes results in smooth and stable motion, reducing vibration and noise.

- Wide Range of Angles: Miter gearboxes can handle a broad range of angle requirements, making them versatile for various applications.

- Enhanced Precision: These gearboxes enable precise positioning and alignment of components, crucial in industries like automotive manufacturing.

- Robust and Durable: Constructed from high-quality materials, miter gearboxes offer durability and can withstand demanding operational conditions.

- Customizability: Miter gearboxes can be designed and customized to meet specific angle transmission needs in different industries.

Overall, miter gearboxes are a valuable solution for applications that require accurate and reliable angular transmission, contributing to improved performance and quality in various industries.

Significance of Angle Between Bevel Gears in a Miter Gearbox

The angle between bevel gears in a miter gearbox is of crucial significance as it determines the direction and type of motion transfer between intersecting shafts. In a miter gearbox, the angle between the bevel gears is typically set at 90 degrees.

This 90-degree angle allows the bevel gears to change the direction of rotational motion by redirecting it along a perpendicular axis. This is particularly useful in applications where space constraints or specific layout requirements demand a right-angle change in motion.

The angle also influences the tooth engagement and meshing characteristics of the bevel gears. Proper alignment and precise calculation of this angle are essential to ensure smooth and efficient motion transmission, minimize backlash, and prevent premature wear on the gear teeth.

The choice of angle between the bevel gears is a fundamental design consideration that directly impacts the functionality, performance, and durability of the miter gearbox in various mechanical systems.

editor by CX 2023-11-30