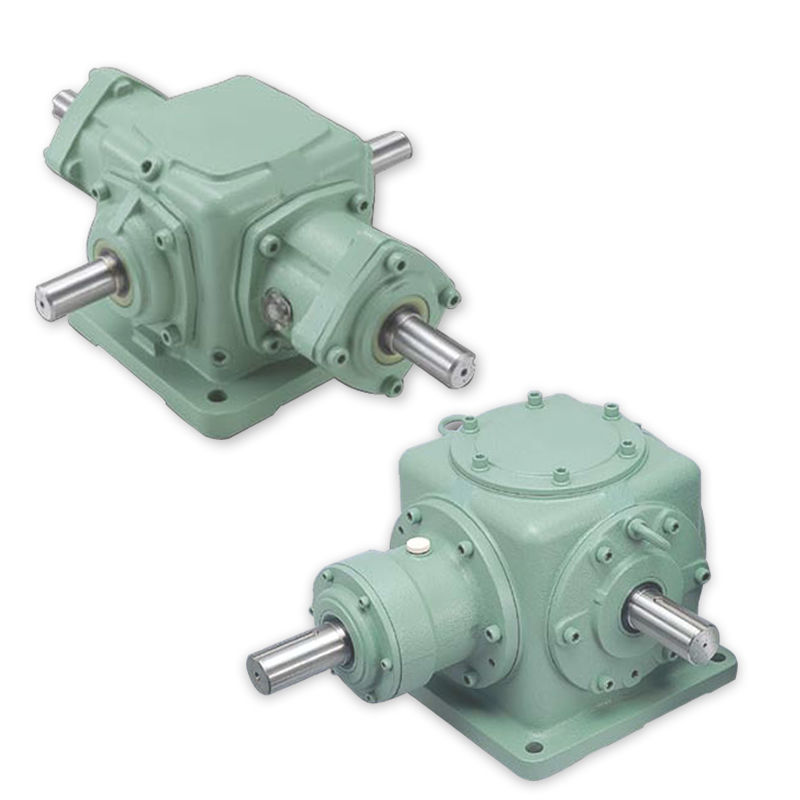

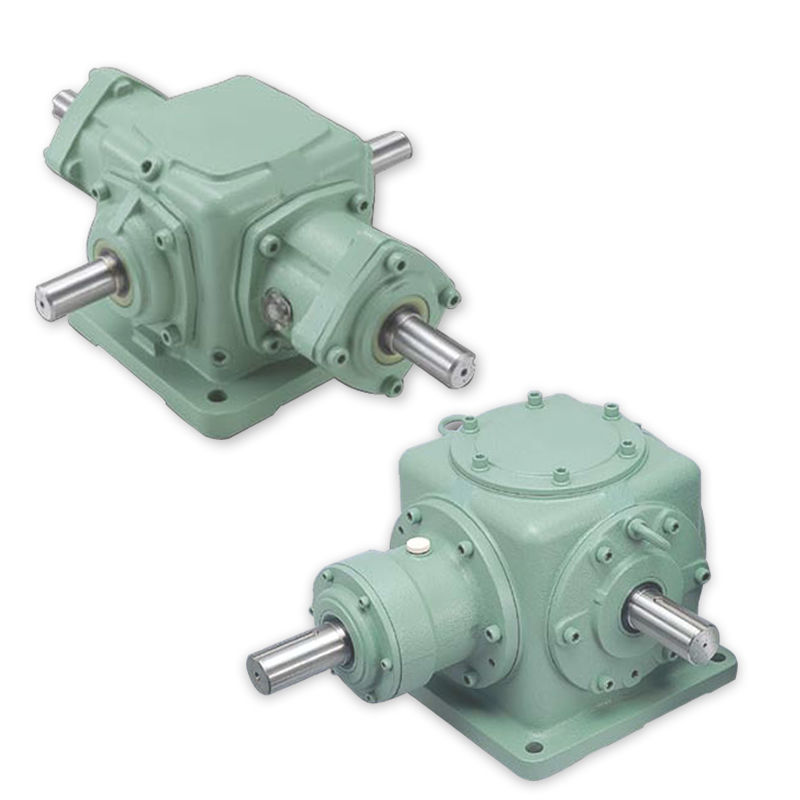

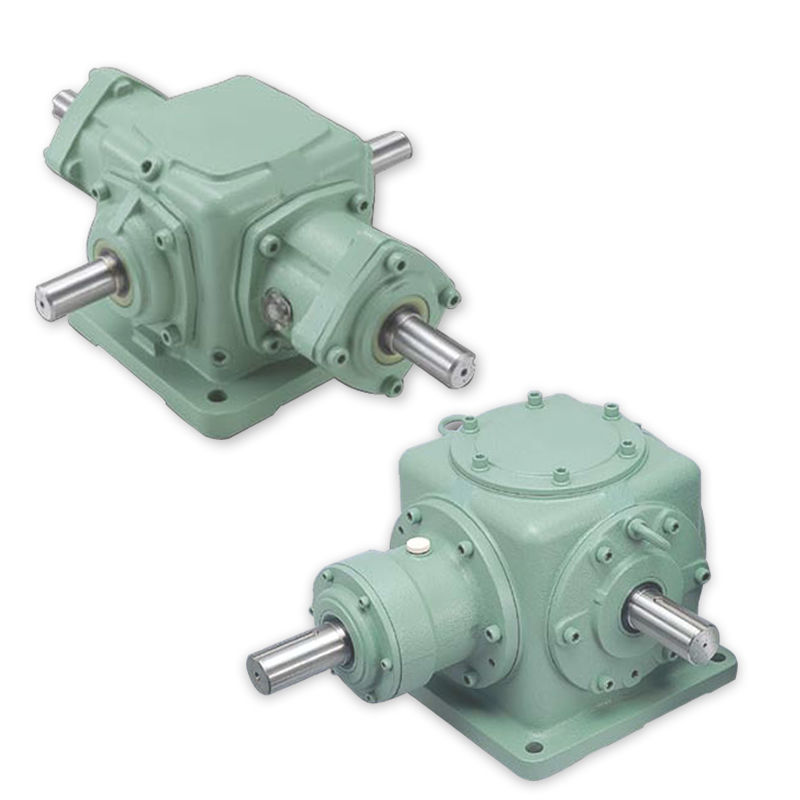

Product Description

Product Description

Product Parameters

| Description |

Feed Mixer Machines Gearboxes – Replacement of Comer Code D-732A 1:1/1.41:1 |

|

|---|---|---|

| Application |

Mixing wagon |

|

| Consists of |

|

|

| Technical information |

|

|

| Contains oil |

No |

|

| Max. oil capacity |

5.6 l |

|

| Max. oil change interval |

500 h |

|

| Oil SAE viscosity grade |

80W-90 |

|

| Housing material |

Cast iron GG25 |

|

| Weight |

63 kg |

|

| Gear arrangement |

231 |

|

| Input shaft Reducing |

X |

|

| Input power KW / HP Reducing |

59 / 80 kW/HP |

|

| Ratio Reducing |

1 : 1 / 1,41 : 1 |

|

| Shaft X |

1 3/8″ (6) (A) |

|

| Shaft Y |

1 3/4″ (6) (G) |

Company Profile

HangZhou Ever-power Transmission Machinery Co., Ltd. was established in 2006. The company is located in ZHangZhoug HangZhou, with 90 employees, an area of 3800 meters, and an annual output value of 40 million yuan. The company is committed to the R & D, manufacturing, and personnel training of various gearboxes, reducers, and construction machinery, including spiral bevel gearbox, spur gearbox, worm gearbox, and cylindrical gearbox. It also includes a variety of high-pressure cast valve body and shell products. Its products are used in various applications, such as agricultural mowers, snow sweepers, fertilizer applicators, grain conveyors, industrial equipment, oil mining machinery, marine industrial equipment, and engineering hydraulic components. More than 95% of its products are exported to Europe, the United States, and Australia. Asia and Canada. The company has strong technology and R & D capabilities, produces reliable and high-quality products, pursues a unique business philosophy and enjoys a high reputation in the manufacturing industry. Welcome to contact us by phone or email.

Our Equipments

Certification

Packaging and Shipment

Related products

PTO Shaft

Agricultural gearbox:

Flail mower gearbox, rotary tiller gearbox, lawn mower gearbox, rotary cutter gearbox, agricultural sprayer gearbox, post hole digger gearbox, feed mixer gearbox, rotary mower gearbox, gearbox for circular saws, irrigation reels gearbox, agricultural generator gearbox, fertilizer spreader gearbox, hydraulic drive gearbox, manure spreader gearbox, rotary rakes gearbox, hay tedders gearbox, micro tiller gearbox, cutter bars gearbox, fertilizer mixer gearbox, agitators gearbox for sewage, round baler gearbox, snowblower gearbox

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Function: | Distribution Power, Clutch, Change Drive Torque, Change Drive Direction, Speed Changing, Speed Reduction, Speed Increase |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) | |

|---|

Minimizing Backlash and Ensuring Efficient Power Transfer in Miter Gearboxes

Miter gearboxes are meticulously designed to minimize backlash and ensure efficient power transfer, contributing to smooth and reliable operation in various mechanical systems.

Backlash, the slight movement or play between mating gears, can lead to imprecise motion and reduced accuracy. To address this, miter gearboxes incorporate features such as precision-machined gear teeth, high-quality bearings, and precise alignment of gears and shafts. These design elements help minimize the clearance between gear teeth, reducing or eliminating backlash and ensuring consistent motion transfer.

Efficient power transfer in miter gearboxes is achieved through careful consideration of gear geometry, tooth profiles, and material selection. Engineers optimize gear tooth shapes to minimize friction and maximize contact area between mating gears. Additionally, high-quality materials with appropriate hardness and surface finish are chosen to enhance durability and reduce energy losses due to friction.

The lubrication system also plays a critical role in efficient power transfer. Proper lubrication reduces friction, dissipates heat, and prevents wear, contributing to the overall efficiency of the gearbox.

Overall, the design of miter gearboxes focuses on tight tolerances, precision manufacturing, and thoughtful engineering to minimize backlash and maximize power transfer efficiency, resulting in reliable and high-performance mechanical systems.

Key Benefits of Using Miter Gearboxes in Angular Transmission Applications

Miter gearboxes offer several key benefits when used in applications requiring angular transmission:

- Precise Angle Transmission: Miter gearboxes excel at transmitting rotational motion at specific angles, ensuring accurate and controlled angular adjustments.

- Compact Design: Their compact and space-saving design allows for efficient integration into machinery and equipment with limited space.

- High Efficiency: Miter gearboxes are engineered for efficient power transmission, minimizing energy losses during angular motion transfer.

- Smooth Operation: The meshing of bevel gears in miter gearboxes results in smooth and stable motion, reducing vibration and noise.

- Wide Range of Angles: Miter gearboxes can handle a broad range of angle requirements, making them versatile for various applications.

- Enhanced Precision: These gearboxes enable precise positioning and alignment of components, crucial in industries like automotive manufacturing.

- Robust and Durable: Constructed from high-quality materials, miter gearboxes offer durability and can withstand demanding operational conditions.

- Customizability: Miter gearboxes can be designed and customized to meet specific angle transmission needs in different industries.

Overall, miter gearboxes are a valuable solution for applications that require accurate and reliable angular transmission, contributing to improved performance and quality in various industries.

Function of Miter Gearbox in Mechanical Systems

A miter gearbox is a type of gear arrangement that allows rotational motion to be transmitted at a 90-degree angle between intersecting shafts. It consists of two bevel gears with perpendicular axes, which makes it suitable for changing the direction of motion in a mechanical system.

Miter gearboxes function by meshing the teeth of the two bevel gears, which are cut at an angle of 45 degrees. As one gear rotates, its teeth engage with the teeth of the other gear, transmitting torque and motion perpendicular to the input shaft. This 90-degree redirection of motion is crucial for applications where space constraints or specific mechanical configurations require changes in direction.

These gearboxes are commonly used in situations where components need to be rotated or aligned at right angles, such as in automotive steering systems, printing presses, woodworking machinery, and more. The ability to efficiently transfer motion at a 90-degree angle makes miter gearboxes essential in various industrial and mechanical applications.

editor by CX 2024-04-09