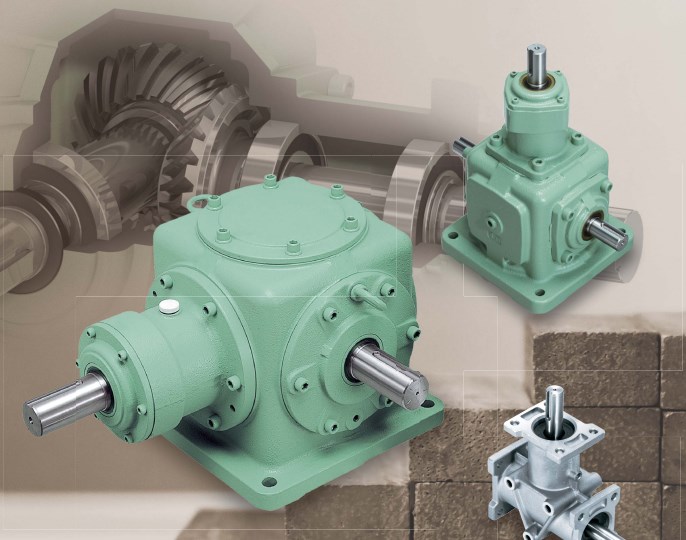

Product Description

China Manufacturer of CHINAMFG Series Hard Tooth Flank Gear Box for Extruder

Description:

ZLYJ gearbox series are transmission devices, which are specially designed for single-screw extruder with high precision, hard gear surface, accompany with thrust. Adopting the technical specifications stipulated in JB/T9050. 1-1999,all CHINAMFG gearboxes are designed accordingly.

Features:

1, The gear is made of high-strength low-carbon alloy steel by carburizing and quenching. The hardness of the tooth surface is up to HRC58-62. The gears are ground grinding technology with high precision and good contact.

2, High transmission efficiency: CHINAMFG is greater than 96.5%, double level is greater than 93%, third level is greater than 90%.

3, Smooth operation and low noise.

4, Small size, light weight, long service life and high carrying capacity.

5, Easy to disassemble and easy to install.

Parameters:

|

Type |

Spec |

Input Power(kw) |

N( enter) |

N(output) |

Output Torque |

Permitted axial thrust of output shaft(KN) |

Screw Diameter |

Length-diameter ratio |

|

(N·m) |

||||||||

|

ZLYJ gearbox |

112-8 |

5.5 |

800 |

100 |

525 |

35 |

Ø35 |

25:01:00 |

|

133-8 |

8 |

800 |

100 |

764 |

39 |

Ø50 |

25:01:00 |

|

|

146-10 |

11 |

1000 |

100 |

1050 |

54 |

Ø55 |

25:01:00 |

|

|

173-10 |

18.5 |

900 |

90 |

1962 |

110 |

Ø65 |

25:01:00 |

|

|

200-12.5 |

30 |

1000 |

80 |

3581 |

155 |

Ø75 |

25:01:00 |

|

|

225-12.5 |

45 |

1000 |

80 |

5371 |

180 |

Ø90 |

25:01:00 |

|

|

250-16 |

55 |

1120 |

70 |

7503 |

192 |

Ø105 |

25:01:00 |

|

|

280-16 |

75 |

960 |

60 |

7643 |

258 |

Ø110 |

25:01:00 |

|

|

315-16 |

85 |

960 |

60 |

13528 |

287 |

Ø120 |

25:01:00 |

|

|

330-16 |

110 |

960 |

60 |

17507 |

360 |

Ø135 |

25:01:00 |

|

|

375-16 |

132 |

960 |

60 |

21008 |

390 |

Ø150 |

25:01:00 |

|

|

395-16 |

185 |

960 |

60 |

29442 |

400 |

Ø160 |

25:01:00 |

|

|

420-16 |

160 |

960 |

60 |

31831 |

430 |

Ø160 |

25:01:00 |

|

|

420-16 |

220 |

960 |

60 |

31831 |

430 |

Ø170 |

25:01:00 |

|

|

450-20 |

213 |

1000 |

60 |

40640 |

500 |

Ø160/Ø170 |

25:01:00 |

|

|

560-17 |

540 |

1000 |

50 |

84034 |

700 |

Ø200 |

25:01:00 |

|

|

630-10 |

540 |

1000 |

50 |

15712 |

770 |

Ø250 |

25:01:00 |

Packing & shipping:

1 Prevent from damage.

2. As customers’ requirements, in perfect condition.

3. Delivery : As per contract delivery on time

4. Shipping : As per client request. We can accept CIF, Door to Door etc. or client authorized agent we supply all the necessary assistant.

FAQ:

Q 1: Are you a trading company or a manufacturer?

A: We are a professional manufacturer specializing in manufacturing various series of couplings.

Q 2:Can you do OEM?

Yes, we can. We can do OEM & ODM for all the customers with customized artworks in PDF or AI format.

Q 3:How long is your delivery time?

Generally, it is 20-30 days if the goods are not in stock. It is according to quantity.

Q 4: How long is your warranty?

A: Our Warranty is 12 months under normal circumstances.

Q 5: Do you have inspection procedures for coupling?

A:100% self-inspection before packing.

Q 6: Can I have a visit to your factory before the order?

A: Sure, welcome to visit our factory.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Industry |

|---|---|

| Function: | Speed Reduction |

| Layout: | Coaxial |

| Hardness: | Hardened Tooth Surface |

| Installation: | Horizontal Type |

| Step: | Three-Step |

| Customization: |

Available

| Customized Request |

|---|

Performance of Miter Gearboxes in Applications Requiring Precise Angle Changes

Miter gearboxes excel in applications that demand precise angle changes in motion transmission. Their ability to efficiently and accurately redirect rotational motion by 90 degrees makes them ideal for tasks where precise angular positioning is essential. Industries such as robotics, automation, machinery, and manufacturing often utilize miter gearboxes to achieve accurate and repeatable angular changes, ensuring proper alignment and movement of components. The compact and space-saving design of miter gearboxes further enhances their suitability for applications that require tight spatial constraints and precise motion control.

Limitations of Torque and Speed in Miter Gearboxes

Miter gearboxes, like any mechanical component, have certain limitations when it comes to handling torque and speed. These limitations are influenced by factors such as design, materials, and manufacturing processes:

- Torque Capacity: The maximum torque that a miter gearbox can handle is determined by the size and strength of the gears, shafts, and housing. Exceeding the rated torque can lead to gear tooth wear, tooth breakage, and even gearbox failure.

- Speed Limitations: The rotational speed of a miter gearbox is limited by factors like the diameter of the gears and the quality of the gear teeth. High speeds can generate heat and cause excessive wear, reducing the lifespan of the gearbox.

- Heat Generation: Excessive torque or speed can lead to increased heat generation due to friction and load. Elevated temperatures can affect the lubrication, material strength, and overall performance of the gearbox.

- Lubrication: Inadequate or improper lubrication can limit the torque and speed capabilities of a miter gearbox. Lubrication helps reduce friction and dissipate heat, enabling the gearbox to handle higher loads and speeds.

- Material Strength: The choice of materials used in the gearbox’s construction influences its torque and speed limitations. High-quality materials with appropriate hardness and tensile strength are essential for withstanding heavy loads and high speeds.

It’s important to carefully consider the specific torque and speed requirements of an application when selecting a miter gearbox. Exceeding the gearbox’s rated limits can result in decreased performance, increased wear and tear, and potential system failures.

Transmission of Motion in Miter Gearboxes

Miter gearboxes transmit motion at an angle between intersecting shafts through the use of bevel gears with perpendicular axes. These bevel gears have teeth that are cut at a 45-degree angle to the gear’s face and mesh with each other. When one bevel gear is rotated, its teeth engage with the teeth of the other bevel gear, resulting in torque transfer and motion redirection at a 90-degree angle.

As the input shaft turns the first bevel gear, its teeth push against the teeth of the second bevel gear. This interaction causes the second bevel gear to rotate around its perpendicular axis, transferring motion to the output shaft. The gear ratio and the number of teeth on each gear determine the speed and torque characteristics of the transmitted motion.

Due to their ability to redirect motion while maintaining efficient power transmission, miter gearboxes are commonly used in applications where a change in direction is necessary, such as in steering systems, printing machinery, and other mechanical systems requiring precise angular alignment.

editor by CX 2024-05-02